CUSTOM MACHINE BUILDER

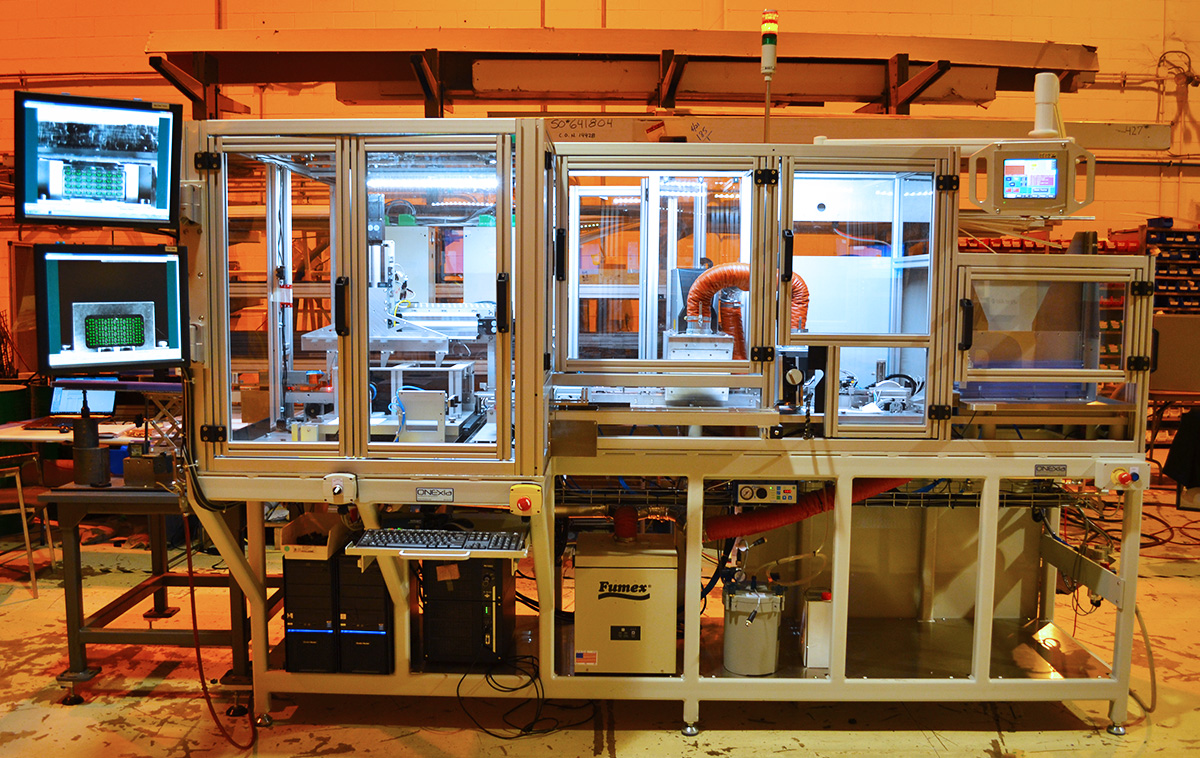

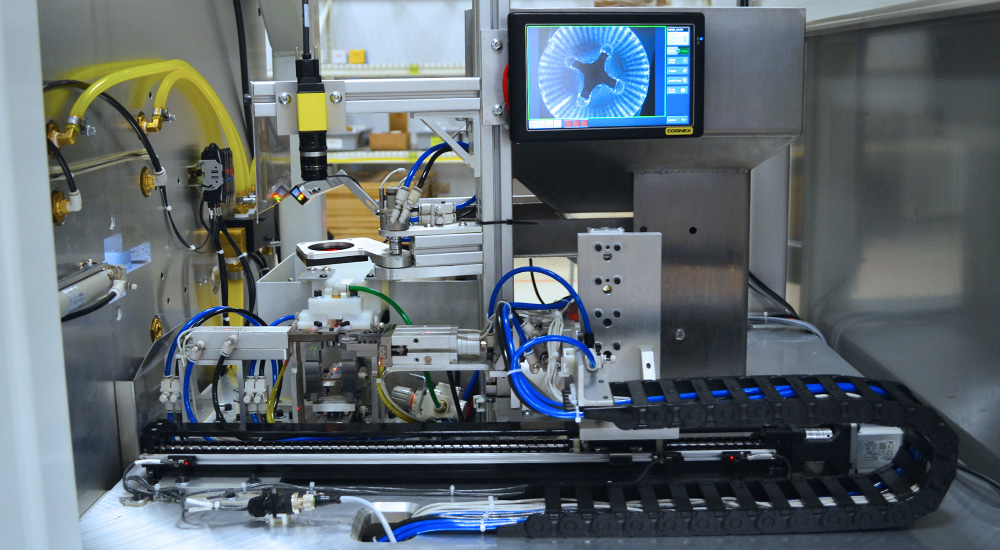

Experts in motion control, precision positioning, and machine vision ONExia designs and builds turn-key machines fully customized to the application.

Machine Building Services

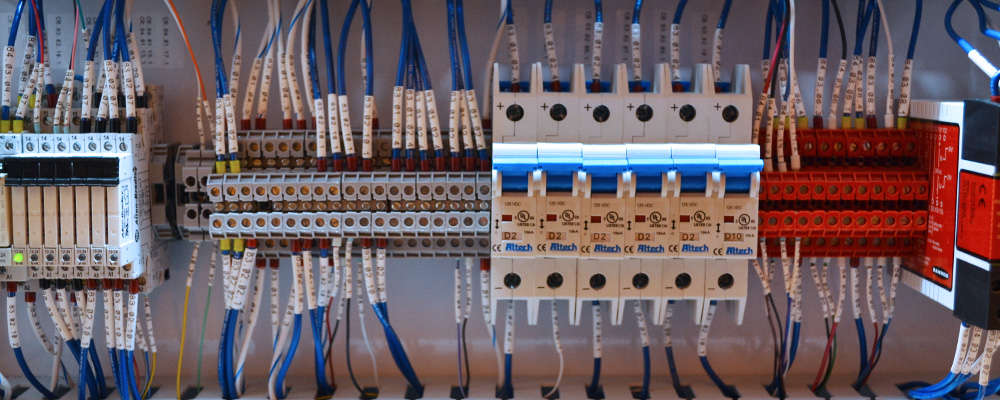

An extension of your engineering staff! From small control assemblies to large scale custom systems ONExia is your source for automation services.

- Turn-key custom machines

- Controls assembly

- Motion control programming

- Precision positioning systems

- 2D & 3D vision systems

- Machine safety services

- Custom software & user interfaces

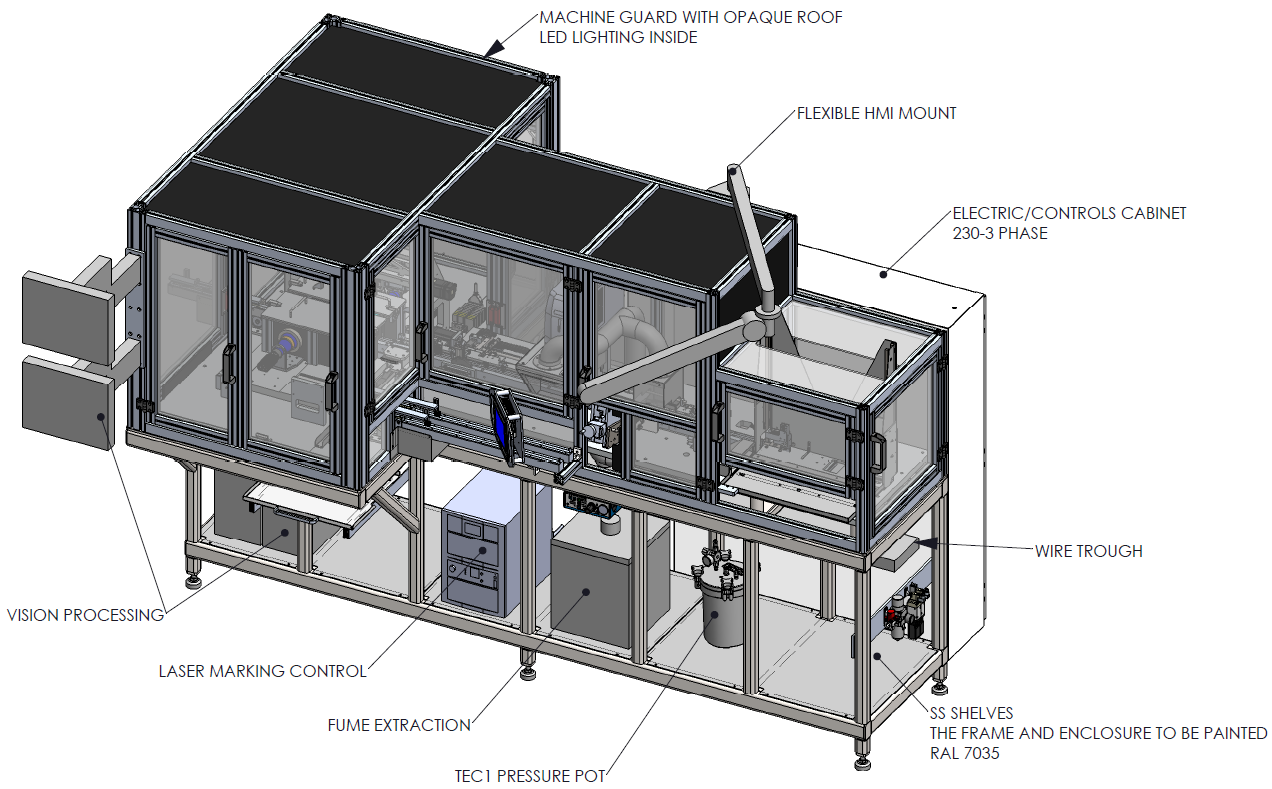

ADVANCED MACHINE DESIGN PROCESS

ONExia follows a refined machine design process that includes direct collaboration between our engineering team and the customer at every step of the build.

From the mechanical design & custom part fabrication to acceptance testing & installation, ONExia’s team of engineers is working with you every step of the way.

Why choose ONExia as your custom machine builder?

With over 35 years of experience ONExia has expert level knowledge of process automation in almost every industry.

ENGINEERING STAFF

A degreed staff of electrical and mechanical engineers with expertise in building one of kind custom solutions.

SOFTWARE DEVELOPMENT

Every turn-key system comes with a custom software package that provides the end-user complete control of the system through a single HMI or PC.

FABRICATION & MACHINE SHOP

Each custom system is designed and built at our facility in Exton Pennsylvania with a majority of the custom parts being cut in house.

CUSTOMER TRAINING, SERVICE & SUPPORT

Following the build, we join your team on-site for SAT and training. After the system is in operation, we continue to support throughout the lifecycle of the machine and provide upgrades and service as needed.

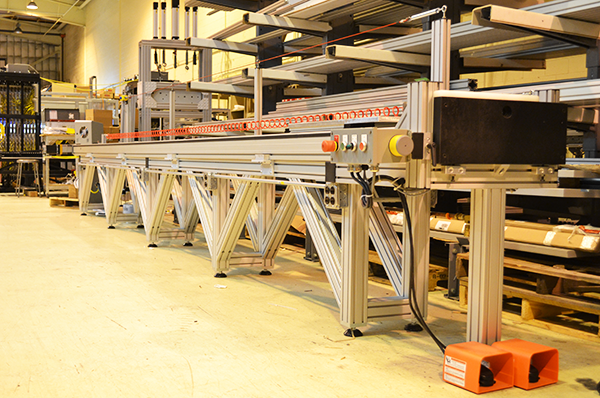

T-Slot Aluminum Frame Design

Using structural T-slot aluminum extrusions, fasteners, panels, doors, hardware and accessories can be configured to meet any design challenge with a durable, high performance solution.

- Cabinets, storage, and workstations

- Material handling systems

- Portable gantry systems

- Machine bases and frames

Build-to-Print & Contract Manufacturing

Our project engineers provide un-paralleled expertise assisting our OEM customers develop and implement new technologies in their machinery.

We can collaborate on a revision to your existing design, or provide complete design, complete with documentation and fabrication services.

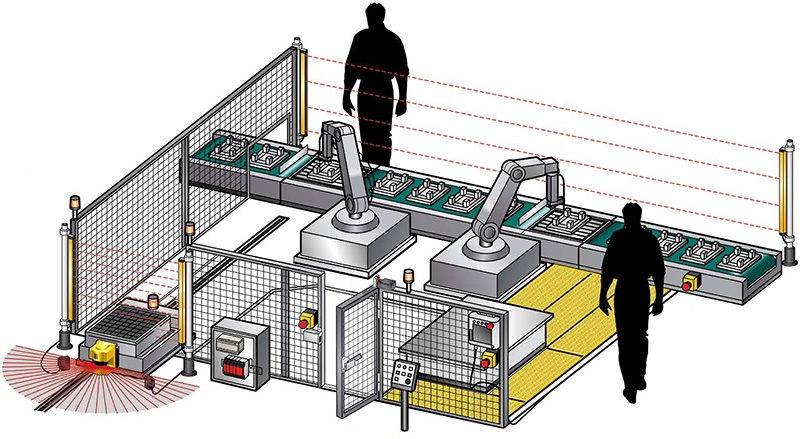

Machine Safety Integration

Partnered with Omron, our goal is to protect personnel and increase overall machine performance. We offer a full line of safety and automation devices that reduce project costs through innovative connectivity.

- Complete range of global safety products

- Education on safety compliance and adoption

- Experts in collaborative and industrial robot safety

- Assessments and Risk Identification

- Engineering and design services

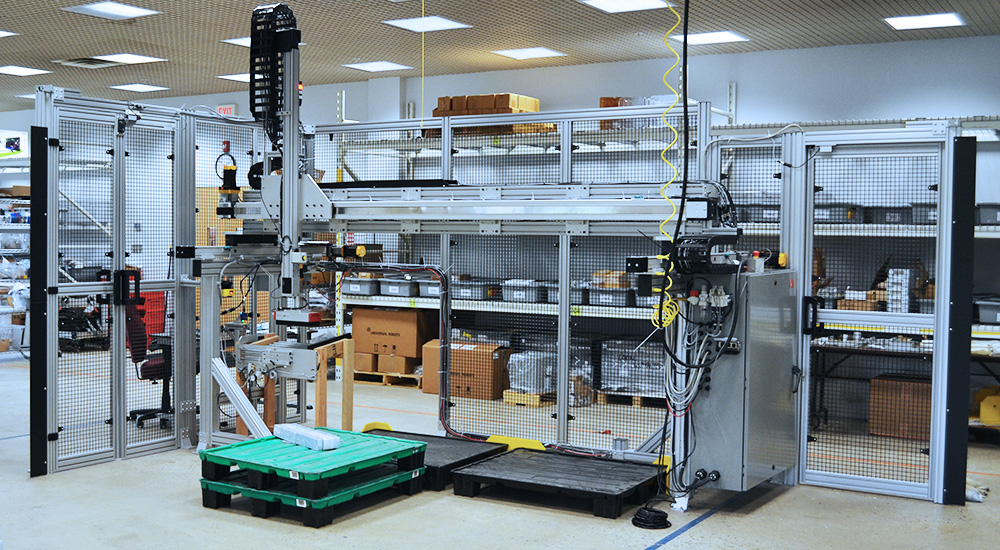

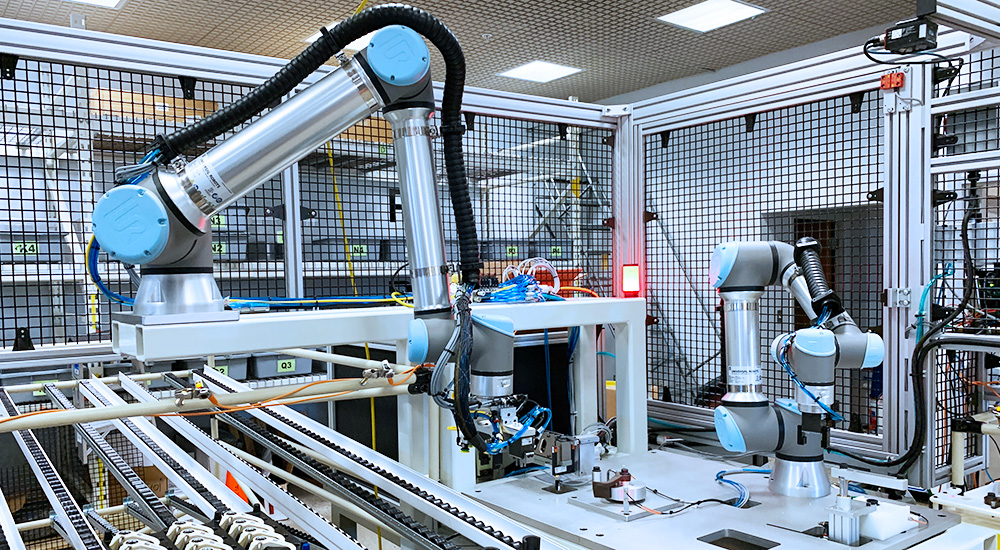

Robot Integration Services

By combining robotic expertise with a background in custom machine building, ONExia’s robotic systems are fully developed, turn-key systems.

- Collaborative & industrial robot cells

- Application & software development

- Robotic safety integration

- Grippers & end of arm tooling

- 2D & 3D vision system integration

Custom machines for the aerospace industry!

Custom machines for the aerospace industry!

ONExia offers a variety of custom machines and tools designed for applications in the aerospace and composites manufacturing industry.

- Laser Light Towers

- Rotor Blade Carts

- Universal Holding Fixtures

- Tooling Carts

- Vacuum Tables

- Custom Systems

Custom Machine Build Inquiry

Fill out the form below and we will get back to you within one business day.