ASYRIL

Asyril develops, produces and markets high performance flexible feeding systems for parts and components from less than 0.1 up to 150mm in size. Their innovative 3-axis vibration technology can handle bulk parts of any geometry and allows for extremely gentle part feeding.

Flexible 3-Axis Vibration Feeders

Asyril's award-winning series of Asycube flexible feeders offers high performance part feeding, pre-orientation and optimal surface distribution of bulk parts and components.

- Compatible with all part geometries : 99% of parts can be fed on our feeders - including complex geometries and delicate materials

- Pre-orientation and gentle separation of components with patented 3-axis system

- Easy settings integration : compatible with all types of robots and PLC

- Minimum production changeover times enable flexible, future-proof production systems

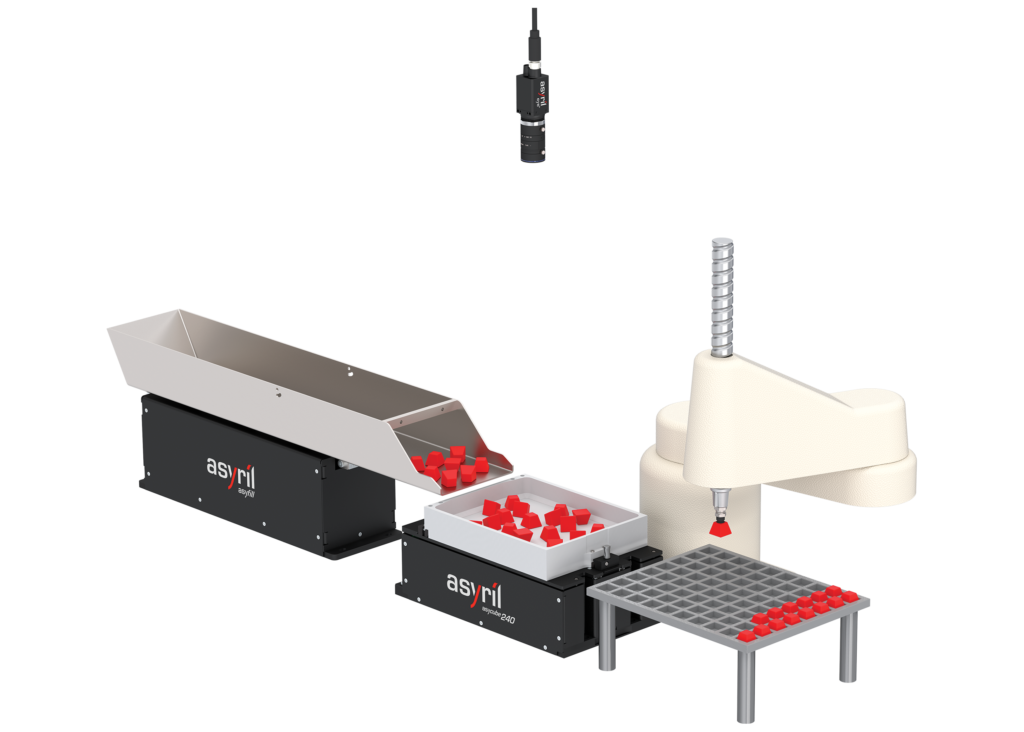

Asycube Flexible Feeding Solution

Asycube 50

Component Size: 0.1-5 mm

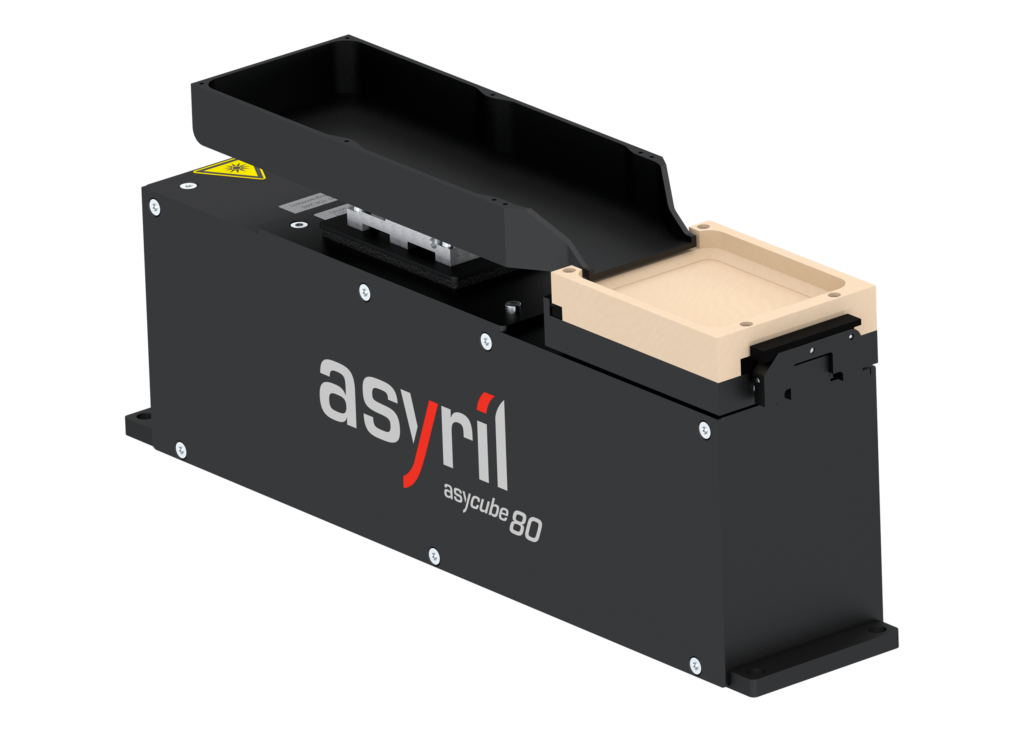

Asycube 80

Component Size: 3-15 mm

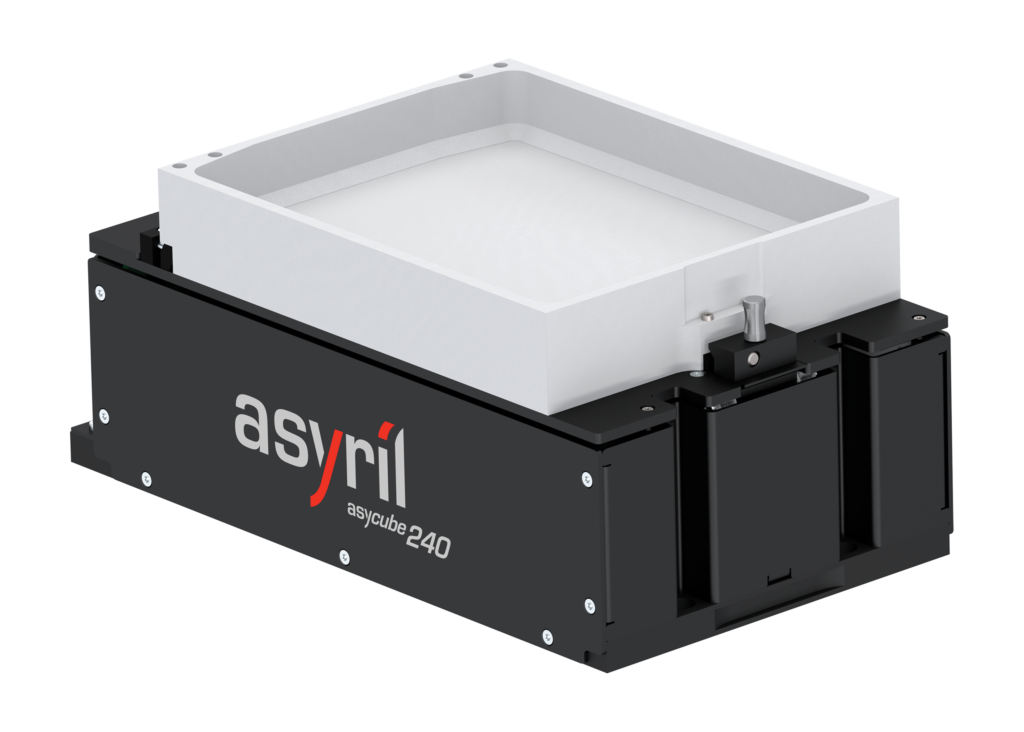

Asycube 240

Component Size: 5-40 mm

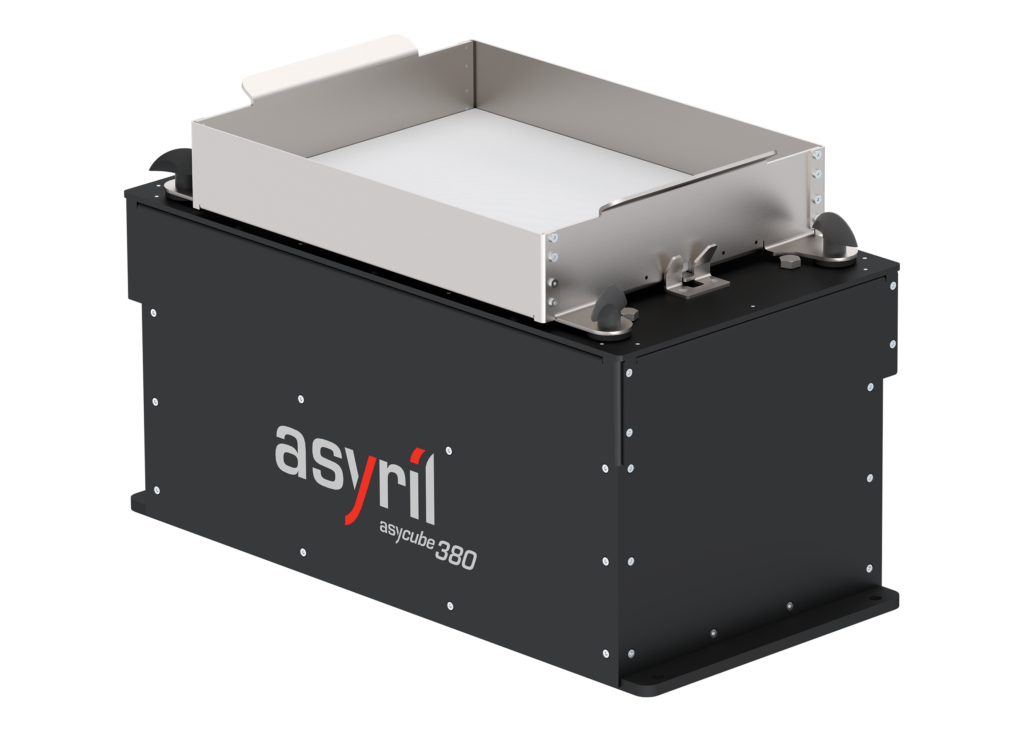

Asycube 380

Component Size: 15-60 mm

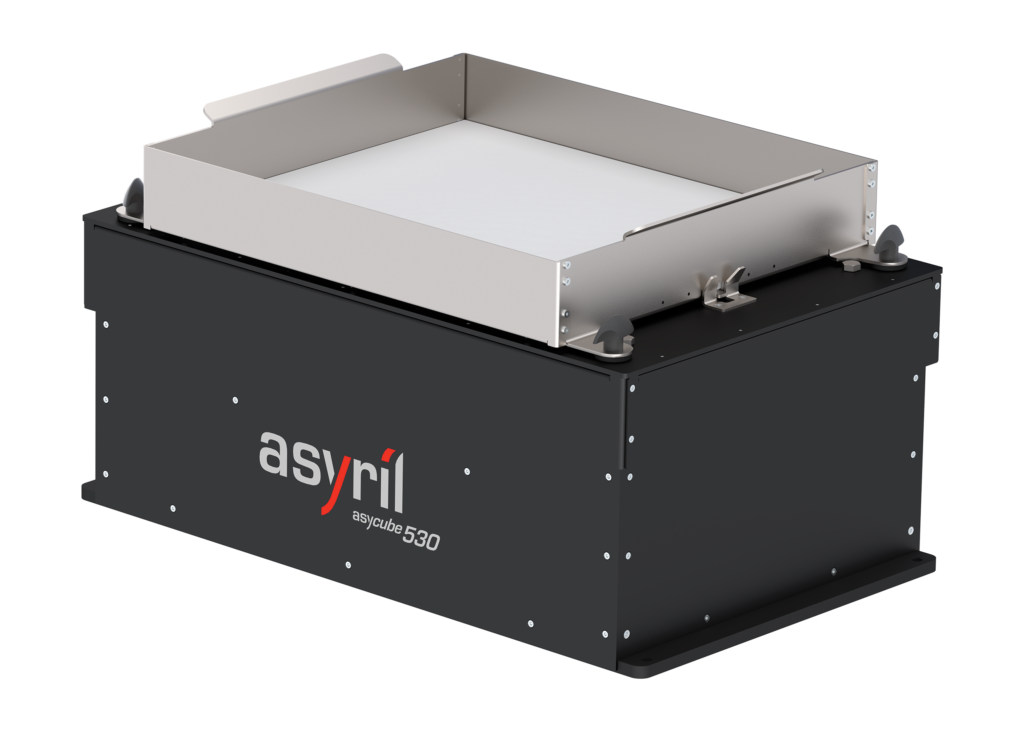

Asycube 530

Component Size: 30-150 mm

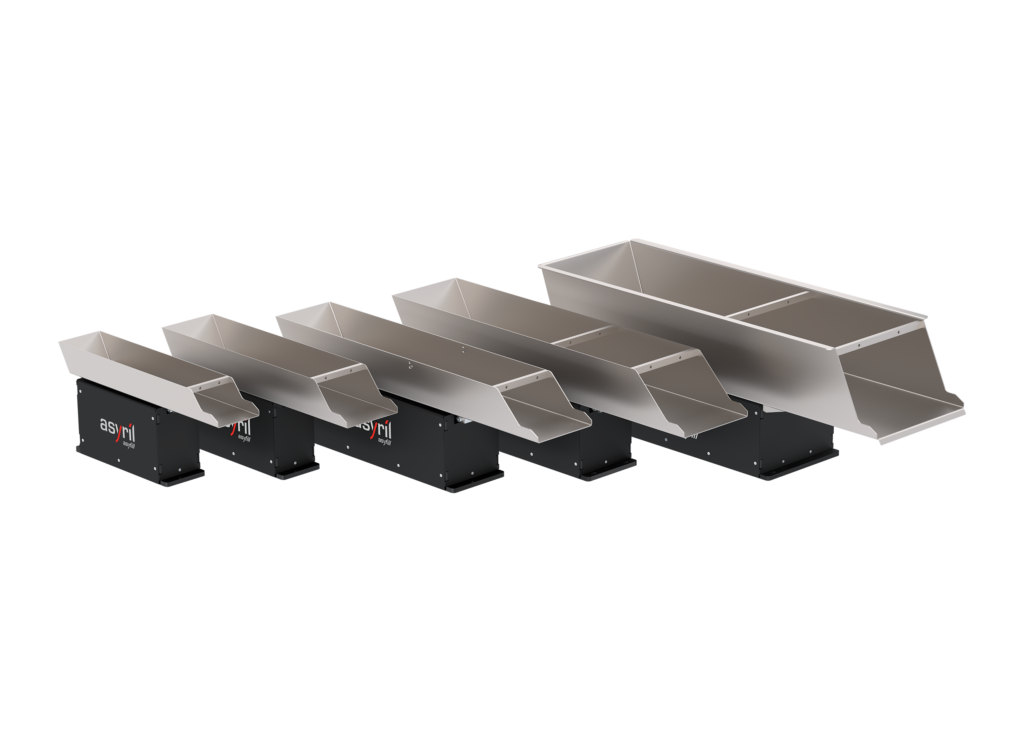

Asyfill Smart Hopper

Optimal part delivery to the Asycube feeder. With an integrated smart sensor using microelectromechanical (MEMS) vibration system control, Asyfill precisely controls the number of parts delivered to the Asycube. The amplitude power constantly adapts to guarantee consistent dosing regardless of how many parts remain in the hopper.

- Constant regulation of parts distributed onto the Asycube feeder

- Set amplitude directly in Asycube Studio or EYE+ Studio without external controller

- 24 VDC operation compatibility without a frequency converter

- Easy integration with Asycube flexible feeder and EYE+ smart control system

Pairing with Asycube

The Asyfill smart hopper comes in five sizes ranging from 1-14 liters. When used in conjunction with Asycube 380 or 530 flexible feeders, a modular fixation kit is required to install Asyfill at the ideal height. The hopper can be mounted on the short or long side of the Asycube feeder.

EYE+ The Smart Control System

EYE+ is the intelligence between the Asyril Asycube and robot. Control the hopper, Asycube, camera and the robot from the EYE+ Studio, a web based interface.

EYE+ optimizes the performance of your Asycube with integrated Artificial Intelligence based vision on a powerful controller.

- Easy to use

- Intuitive recipe creation

- Plug and play

- Compatible with any PLC & robot brand

A Ready to Deploy Solution

EYE+ consists of a compact controller, a high resolution camera, a calibration plate and a power cable. This system allows the control of the hopper, the Asycube – our flexible feeder-, the camera and the robot via the EYE+ Studio web interface.

Vision Guided Bin Picking

Introducing Merlin by Asryil. Designed to handle parts up to 300 mm, the newest concept utilizes AI based vision to fully pick parts from a bin without leaving any behind.

- Handle parts up to 300 mm (12 in)

- Teach parts from CAD files with an intuitive web interface

- Immune to different lighting conditions thanks to integrated lighting and AI-teaching

- Surround cameras detect pickable parts even during robot movement

- No complex robot joint moves or trajectories

- Constant cycle time through the very last part in the bin

- Compatible with heavy and vibration-sensitive parts

Asyril with Universal Robots

Asyril’s URCaps plugin guarantees a seamless and fast integration of any Asycube in conjunction with any Universal Robot. The control menus are directly accessible from the teach pendant, making it easy to use and quick to implement.