ROBOTIC PACKAGING MACHINERY

Automate the dull and ergonomically unsafe tasks associated with end-of-line packaging operations. Our robotic packaging machinery is turn-key and designed to fit into both new and existing operations.

Turn-key Line Automation

- Flexible – easily retooled and repurposed as production demands change

- Minimal footprint – no caging or guarding needed to operate

- Safe design – meet high level industry standards that assure worker safety in collaborative applications

- Easy to operate – simplified graphic software designed for non-technical users

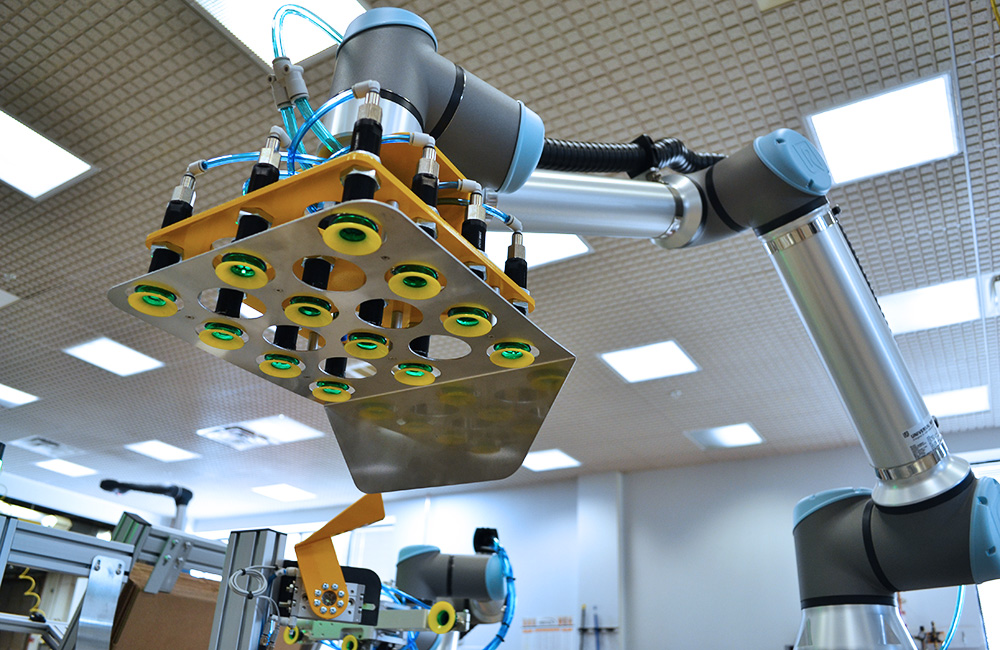

COLLABORATIVE PACKAGING ROBOTS

By using cobots, ONExia’s turn-key robotic packaging machinery is easily added to existing lines – automating the dull, repetitive tasks that are susceptible to labor challenges.

Multi-station Packing Systems

Robotic Case Erectors and case packers can be combined into a turn-key packaging cell.

- Operated through a single touchscreen interface

- Designed to align with existing conveyors

- Minimal footprint automation

ROBOTIC PALLETIZERS

Our palletizers are not kits.

Products of ONExia, each system is designed with the features needed to automate palletizing safely and successfully using a cobot.

- Minimal footprint – no caging or guarding needed to operate

- Quick deployment – requires a 110v outlet and an air line

- Portable – built-in fork pockets within the welded base

PalletizHD Robotic Palletizer

The “HD” is the most robust cobot palletizer on the market, automating the most challenging line tasks.

- High payload – handle case weights up to 38 lbs, or pick multiple lighter cases at once for increased output

- Vertical reach – stack pallets up to 105 inches in height

- Production speed – runs a consistent rate of 7 picks per minute