ROBOTIC SYSTEMS INTEGRATOR

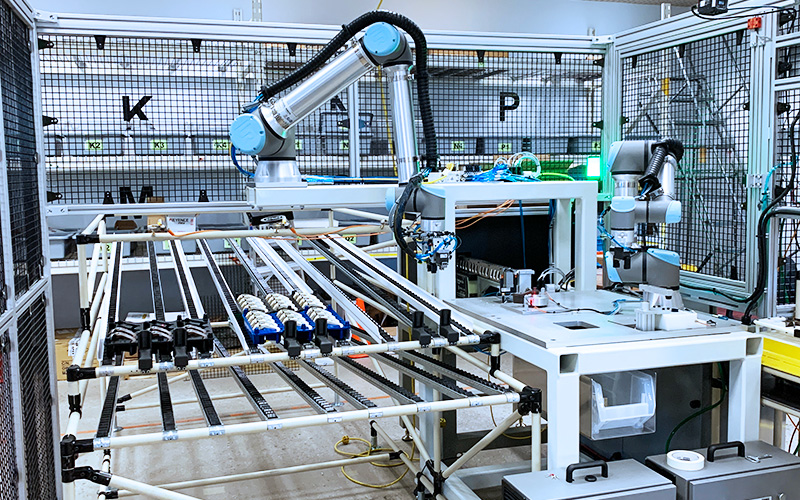

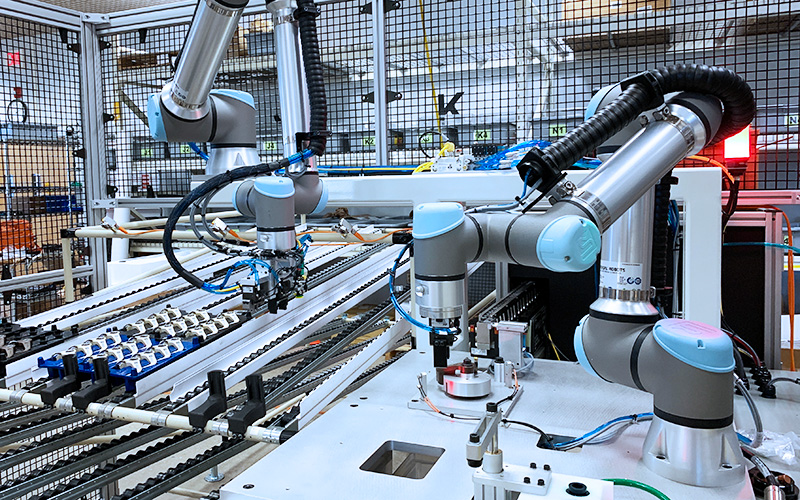

Experts of both collaborative and industrial robots, ONExia is a robotic systems integrator that works with manufacturers of all sizes to automate processes with robotic cells designed specific to their applications.

Robot Integration Services

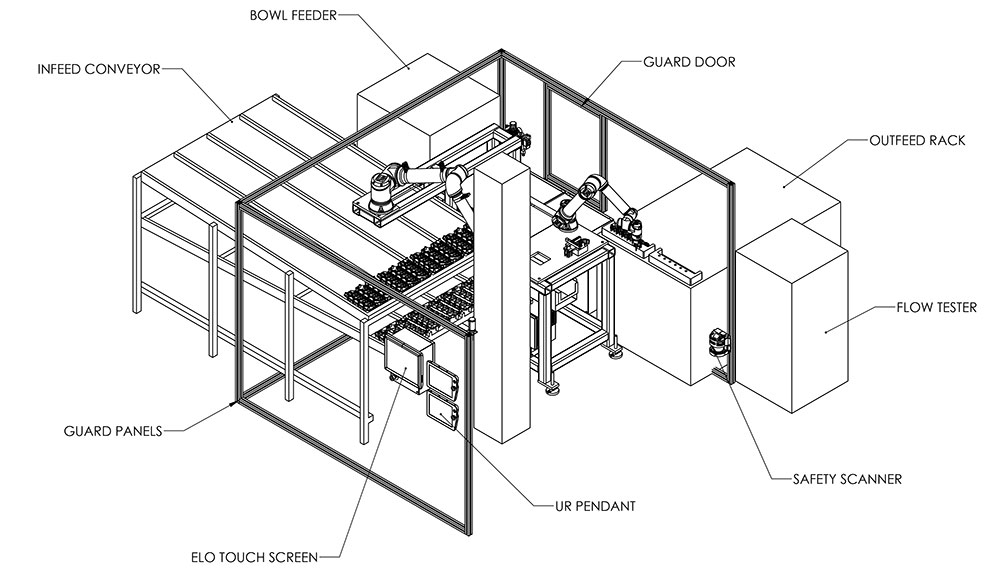

Every turn-key system is designed, built and tested at our facility in Pennsylvania.

- Collaborative robot cells

- Industrial robot cells

- Application & software development

- Robotic safety integration

- Grippers & end of arm tooling

- 2D & 3D vision system integration

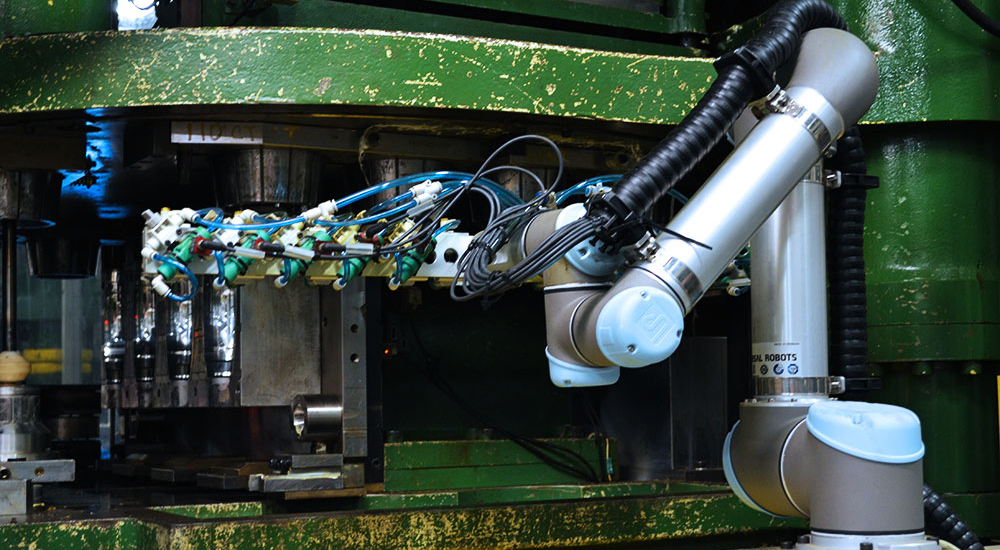

Collaborative Robots

With 10 years of experience working with collaborative robots, ONExia has expert level knowledge needed for successful cobot deployment.

WHAT IS A COBOT?

Collaborative robots or “cobots” are designed to work safely alongside humans. Unlike industrial robots, cobots detect force and stop if a collision is detected.

- Minimal footprint – no caging or guarding needed

- Quick deployment – easily added to existing processes

- Flexible automation – easily adjusted for production changeover

COLLABORATIVE ROBOT PARTNERS

Click the logos to learn more about our partners.

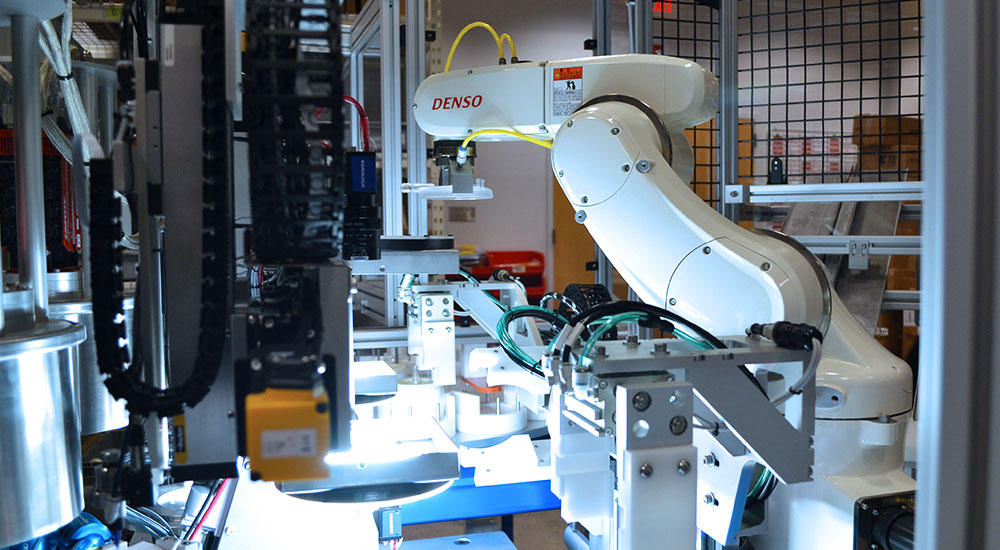

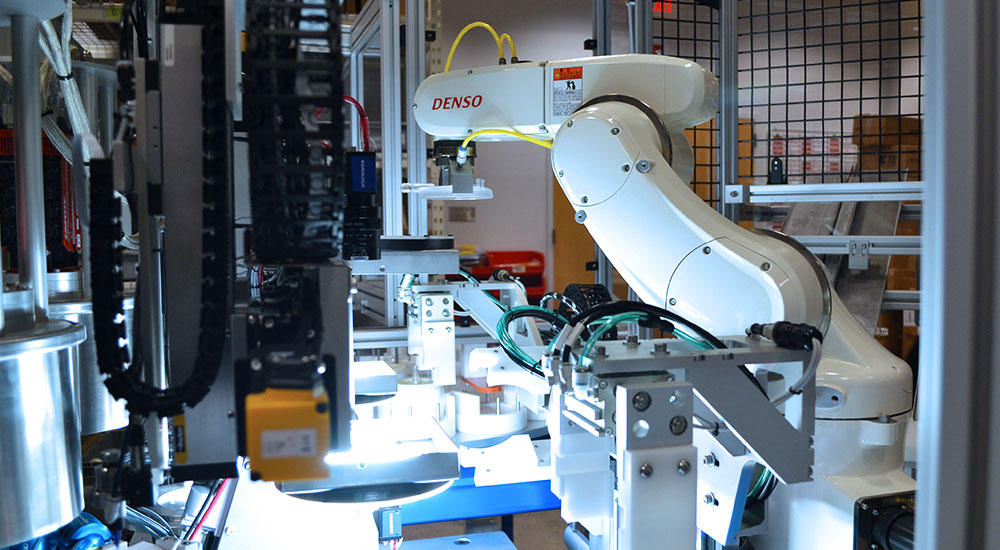

Industrial Robots

Specializing in custom automation, specifically machine vision and motion control, ONExia provides turn-key robotic cells with submicron precision capability.

WHAT IS AN INDUSTRIAL ROBOT?

Traditional industrial robots provide high level precision and speed for advanced process automation.

- Performance – automate processes that require a high level of precision and speed

- Payload – motors and controls for moving weights beyond human capability

- Rigidity – work in environments not suitable for skilled laborers

PREFERRED INDUSTRIAL ROBOTS

Why choose ONExia as your robotic systems integrator?

Our speciality is turn-key. By combining our machine building background with industry leading robotic technology, each system follows a rigorous design process, assuring each requirement is met.

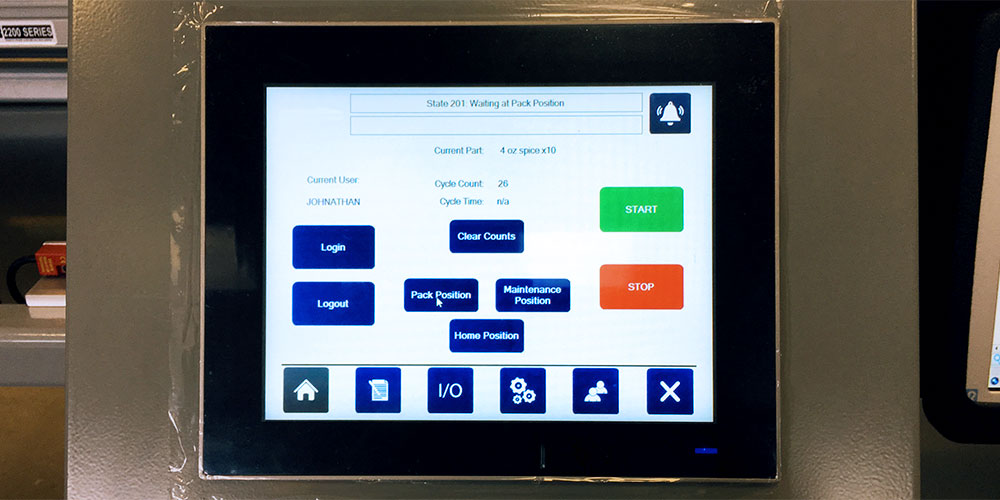

ROBOTIC SOFTWARE

Custom designed for every system, our software gives daily operators complete control of high level automation through a simple HMI or PC interface.

- Machine-to-machine communications

- Data collection & database interaction

- Custom application programming

- Graphic interface design (UX)

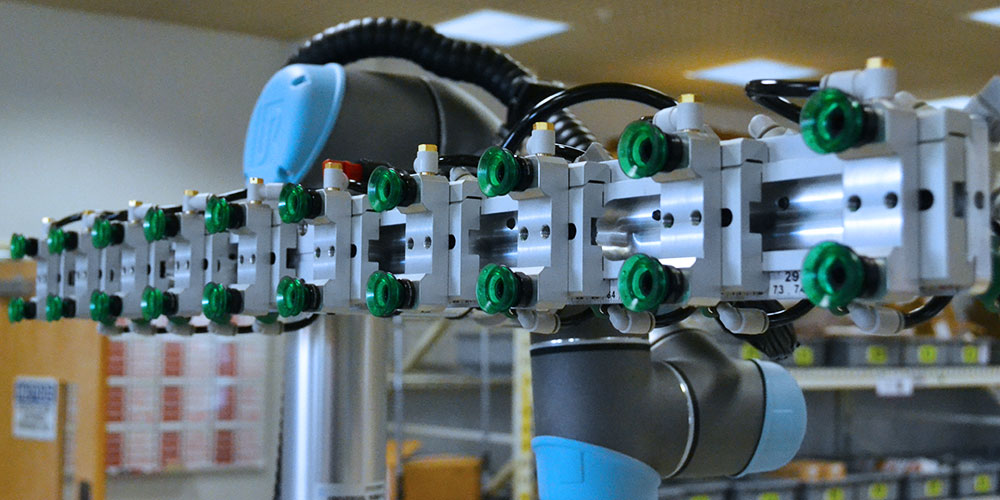

CUSTOM GRIPPERS & TOOLING

Utilizing our internal machining and 3D printer, each robot is tooled with the accessories needed for a successful deployment.

- Part presentation

- Multi-function grippers

- Dispensing systems

- Pneumatic grippers

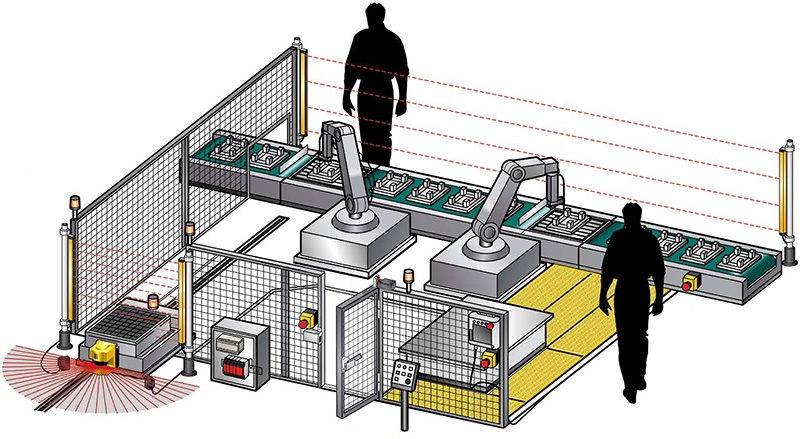

ROBOTIC SYSTEM SAFETY

Every custom robotic cell designed by ONExia meet the industry standards for robotics in manufacturing applications.

Specializing in both collaborative and industrial robot technology, our engineers work directly with each customer to assure their employees are safe when interacting with the cell.

PRE-SALE SERVICES

- Demonstrations of products that are needed for your application

- Proof of concept where we take actual parts and provide video for the customer to review

- Detailed quotation of all the components needed for building the robotic cell

AFTER SALE SUPPORT

- On-site training and integration of the completed project

- Warranty troubleshooting and repairs on-site if needed

- Additional accessories, tooling, and upgrades as applications change

- Continued support through additional deployments

Machine Safety Integration

Partnered with Omron, our goal is to protect personnel and increase overall machine performance. We offer a full line of safety and automation devices that reduce project costs through innovative connectivity.

- Complete range of global safety products

- Education on safety compliance and adoption

- Experts in collaborative and industrial robot safety

- Assessments and Risk Identification

- Engineering and design services

Manual Process Automation Using Robots

Consider us an extension of your engineering staff. Our team works directly with every customer to assure the robotic cell meets their production goals.

MATERIAL HANDLING

Automate repeative machine tending and picking tasks that are ergonomically difficult or unsafe for humans to do.

- Machine tending

- Plastics manufacturing

- Part presentation

ELECTRONICS MANUFACTURING

High level process automation for the assembly and inspection of electronic components with submicron precision.

- Component assembly

- Glue dispensing automation

- Part orientation

MEDICAL DEVICE ASSEMBLY

Unparalleled expertise in complex part assembly cells that meet high level specifications.

- Multi axis positioning systems

- Machine vision inspection

- Adhesive dispensing & curing

Manual Process Automation Using Robots

The answer to your labor shortage! ONExia Robotics is a division of our engineering team focused on building turn-key robotic solutions for end-of-line packaging automation.

- Turn-key packaging lines

- Robotic case erectors

- Robotic case packers

- Robotic palletizers

- Vision integration

- Conveyor integration

AGV / AMR Customizations

ONExia’s integration skills can also be applied to mobile robots and AGVs. Our team has the knowledge needed to customize mobile units to maximize their output.

- Custom mobile conveyor tops

- Software modifications

- Safety integration

- Robotic arm integration

- Custom application programming

Custom Robotic Cell Inquiry

Fill out the form below and we will get back to you within one business day.