MACHINE SAFETY INTEGRATION

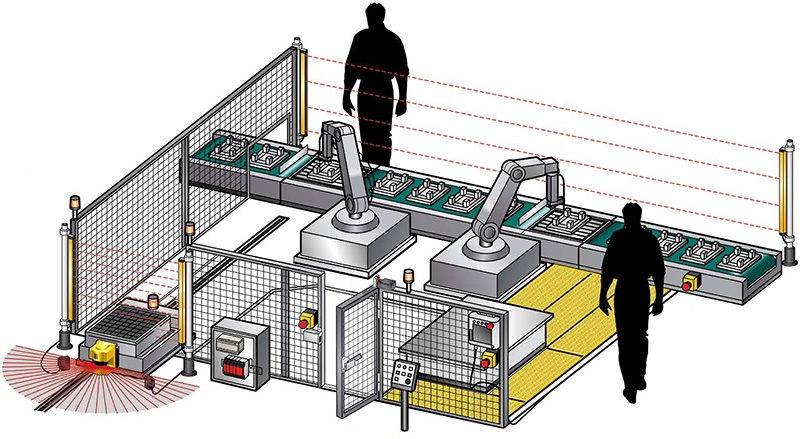

Specialists in turn-key automation, ONExia’s custom integration projects are designed to meet industry standards using cutting edge machine safety technologies.

Productive & Safe Custom Automation

Partnered with Omron, our goal is to protect personnel and increase overall machine performance. We offer a full line of safety and automation devices that reduce project costs through innovative connectivity.

Why work with ONExia?

- Complete range of global safety products

- Education on safety compliance and adoption

- Experts in collaborative and industrial robot safety

- Assessments and Risk Identification

- Engineering and design services

Omron Safety Scanner

The Omron OS32C Safety Laser Scanner offers a compact body for installation in small spaces, e.g. automated guided vehicles and the detection angle up to 270° provides coverage of two sides with just one scanner.

VERSATILE SOLUTION

- For collision avoidance of AGVs (Automated Guided Vehicles)

- For intrusion detection through an entrance

- For presence detection within a machine’s hazardous area

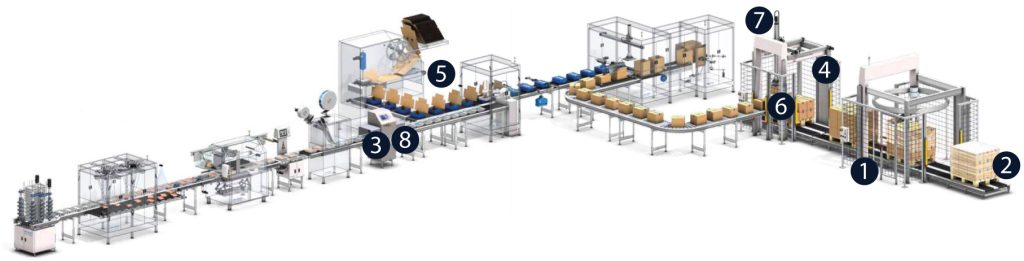

Machine Safeguarding Products

1. DOOR SWITCHES

D4SL Guard lock Safety Door Switch Prevent workers from being trapped inside hazardous areas of equipment with this switch and slide key, lockable in the open position with a trapped keys that can’t be closed until the area is clear.

2. LASER SCANNERS

OS32C Safety Laser Scanner If access to the safety hazard covers a large area use non-contact sensing to prevent equipment start-up or shut down when an intrusion occurs. Built-in EtherNet/IP allows remote device monitoring of status and information.

3. CONTROLLERS

NX Series Modular Safety I/O System Build a safety control system with compact modular I/O that directly integrates and connects to Omron NJ and NX controllers using Safety over EtherCAT, or connects to your standard automation controller using Safety over EtherNet/IP. Use NX-S to build a modular I/O system with up to 256 or 1024 I/O.

4. LIGHT CURTAINS

F3SG-RA Advanced series with F3W-MA Muting Actuators When parts need to flow in and out of hazardous areas without stopping equipment this combination provides a plug and play solution.

5. SAFETY MATS

UMQ Universal Mats with Quick Disconnect Whether you are trying to shutdown equipment or prevent it from starting up safety mats provide personnel detection in the harshest of environments.

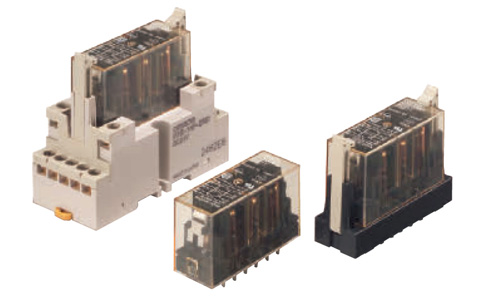

6. RELAYS

G7SA / G7S-E Safety systems from the simplest to the most complex use these relays to switch different voltages and higher currents, and monitor faults.

7. MOTION & DRIVES

G5 Servo Systems and MX2 Frequency Inverters These products incorporate safety functionality with safe inputs to directly remove power to the output actuators without the need for additional hardware. Feedback is provided to ensure that the power has been removed.

8. MODULES

NJ and NX7 Series Machine Automation Controllers Simplify the integration of your safety systems with the NJ and NX series controllers. The EtherCAT network architecture delivers speed and ease of connectivity to seamlessly integrate the NX-S safety unit.