ROBOTIC PALLETIZERS

Specialists in motion control and robotics, ONExia’s robotic palletizers and stackers automate the end of line task of stacking product for shipment.

Collaborative Robot Palletizers

ONExia’s palletizers are not kits.

Each system is designed with the features needed to automate palletizing safely and successfully using a cobot.

- Minimal footprint – no caging or guarding needed to operate

- Quick deployment – require a 110v outlet and an air line

- Portable – built-in fork pockets within the welded base

- Multi-pallet reach – stack pallets on either side of the cobot

- Flexible design – easily adjusted for new pallet configurations

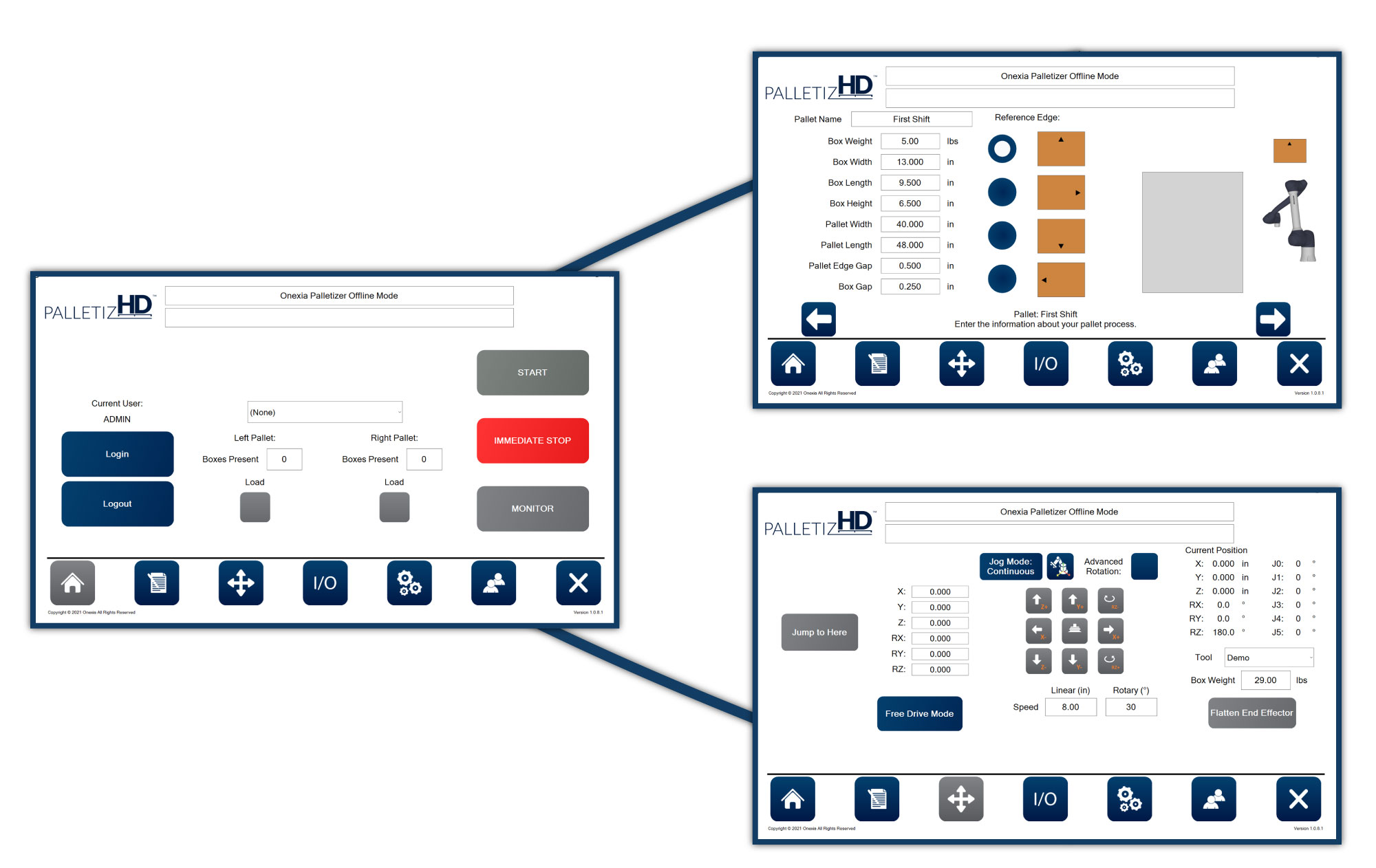

Drag-and-drop Pallet Building

Robotic automation without writing a line of code.

Build and save custom pallet configurations without writing a line of code using ONExia’s drag-and-drop cobot palletizing software.

- Simple interface – designed for non-technical end users

- Pallet library – build, edit, and save hundreds of configurations

- Adminstrative controls – limit access based on user credentials

- Dual mode – tend two separate lines with on system

Why you need a ONExia Palletizer

This is more than just a robot placing cases on a pallet.

Every palletizing application is reviewed by the ONExia team of engineers and is delivered as a fully developed, production ready solution.

COLLABORATIVE SAFETY

- Third party verified to meet the industry standards for collaborative system safety

- Plug-and-play area scanners with customizable safety zones

- Integrated safety devices on custom infeed conveyors

CONVEYOR INTEGRATION

- Designed to the height and width of existing configurations

- Optional indexing sensors for eliminating back pressure from heavier cases

- Hand adjusted nest points for varying case sizes

END OF ARM TOOLING

- Custom designed cup arrays for each application

- Light weight to maximize payload

- Optional multi-pick functionality

- Quick disconnect air lines and slide on tool changer

PalletizHD Robotic Palletizer

The “HD” is the most robust cobot palletizer on the market, automating the most challenging line tasks.

- High payload – handle case weights up to 38 lbs, or pick multiple lighter cases at once for increased output

- Vertical reach – stack pallets up to 105 inches in height

- Production speed – runs a consistent rate of 7 picks per minute

PalletizCRX FANUC Palletizer

Using the new CRX line of cobots, The PalletizCRX is FANUC palletizer users looking for a collaborative solution.

- Minimal footprint – no caging or guarding needed to operate

- No programming – drag-and-drop palletizing software

- Portable – moved with fork lift or pallet jack

PalletizUR Collabortive Palletizer

Designed for Universal Robots, the PalletizUR is a flexible cobot palletizing solution that features 10 kg, 20 kg, and 30 kg options for payload capacity.

- Minimal footprint – no caging or guarding needed to operate

- No programming – drag-and-drop palletizing software

- Portable – moved with fork lift or pallet jack