The PalletizUR is not a kit, it is a turn-key solution.

The PalletizUR is designed with the features needed to automate palletizing safely and successfully using a cobot.

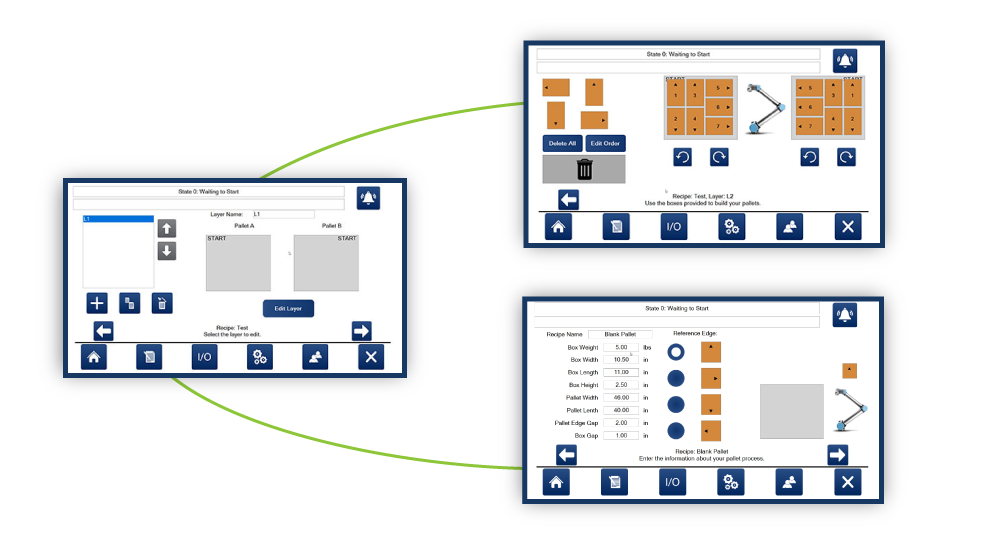

Build and save custom pallet configurations without writing a line of code using ONExia’s drag-and-drop cobot palletizing software.

The PalletizUR runs at collaborative speed out of the crate with no additional safety required.

Area Scanners*

Slows robot if someone is in work area

Hard Guarding*

Complete guarding for work-cell