PARKER

Parker is the global leader in motion and control technologies, providing precision-engineered solutions for a wide variety of mobile, industrial and aerospace markets.

With over 35 years of motion control and precision positioning experiece, ONExia is your source for sizing and integration service for Parker components.

Electromechanical & Drives

Parker controllers provide multi-axes, coordinated motion control for electromechanical, hydraulic and pneumatic motion systems.

Products include stand alone multi-axis motion controllers, intelligent drives and mobile controllers as well as a complete range of supporting accessories.

Parker Motors, Drives, and Controllers

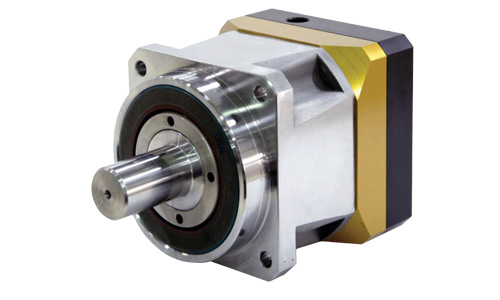

Gearheads, Gearboxes, and Speed Reducers

Parker's broad array of gearhead, gearbox, and speed-reducer solutions offer high torque, high radial loads, low backlash, high input speeds, and small package sizes.

- PTN Series - economic inline planetary gearboxes

- PE Series - standard precision inline planetary gearboxes

- PS Series - high precision inline helical planetary gearboxes

- GXA Series - high precision inline planetary for ATEX applications

High Precision Right-Angle Helical Planetary Gearheads - RS Series

The RS Series helical planetary gearheads feature compact right-angle design and 60-220 mm frame sizes. The precision machined gearbox offers high torque, high radial loads, low backlash, high input speeds and a small package size.

Full Description

Parker’s RS-series planetary gearheads provide the highest performance to meet your applications torque, inertia, speed and accuracy requirements. The right angle design ensures a compact envelope size making it an easy fit in the smallest of spaces. Available in multiple frame sizes and ratios to meet a variety of application requirements.

Features and Benefits

- Right angle design to decrease overall gearhead and motor length

- Helical gears provide more torque capability, lower backlash, and quiet operation

- Ring gear cut into housing provides greater torsional stiffness

- Widely spaced angular contact bearings provide output shaft with high radial and axial load capability

- Plasma nitride heat treatment for gears for excellent surface wear and shear strength

- Sealed to IP65 to protect against harsh environments

- Mounting kits for direct and easy assembly to hundreds of different motors

Servo and Stepper Motors

Parker offers a complete range of rotary and linear electric motors, suitable for a variety of markets and applications.

- Brushless Servo Motors

- DC Brushed Servo Motors

- Frameless Kit Motors

- Stepper Motors

Low Power Compact Brushless Servo Motors - P Series

The P-Series brushless synchronous servo motor offers a compact and economical solution for low power rotary motion, with high performance from a small package size. Featuring high-resolution absolute encoders and seamless integration with Parker P-Series drives, it ensures smooth, high-performance operation and quick, error-free setup.

Full Description

The P-Series brushless synchronous servo motor provides an economical solution for low power rotary motion applications. Available in 40, 60 and 80mm frame sizes, with power ratings from 50 to 1000 watts, its design provides smooth operation with very high performance in a small package size. Rated speeds up to 3000 RPM and continuous stall torque from 0.16 to 3.18 Nm (1.4 to 28.1 in-lb) cover a wide variety of applications. P-Series motors are available with an 18 or 19-bit absolute encoder with BiSS-C interface. This motor is an excellent match to the Parker P-Series drive, as its data will be automatically communicated to the drive for quick and error free set up.

Features:

- Three frame sizes to fit a wide variety of applications

- Auto-configuration when used in combination with Parker P-series servo drives reduces commissioning time

- Compact design fits into tight spaces

- High dynamic performance for shorter cycle times

- Holding brake option available

- Absolute encoder with BiSS-C interface feedback option

- CE certification

Spec Documents

Automation Controllers

Parker controllers provide multi-axes, coordinated motion control for electromechanical, hydraulic and pneumatic motion systems.

- PACIO - Remote I/O System for use with Parker Automation Controller (PAC)

- Parker Motion Controller - PAC Series

Machine Drives

Parker's industry-leading driver offerings include a broad selection of AC variable-speed and frequency drives, analog and digital DC drives, and other servo drives.

- AC and DC Drives

- Mobile Inverter Drives

- Servo Drives and Servo Drive/Controllers

- Stepper Drives and Stepper Drive/Controllers

Human Machine Interface

Parker controllers provide multi-axes, coordinated motion control for electromechanical, hydraulic and pneumatic motion systems.

- Interact Xpress XPR2 Series - Distributed HMIs

- PAC Terminal Thin Client HMI

Parker Automation Controller - Series PAC120

The Parker PAC120 Automation Controller is a compact, modular PLC designed for fast and precise hydraulic process automation, capable of controlling up to 40 hydraulic axes with integrated software and EtherCAT master functionality. The compact PLC enables higher efficiency and product quality in demanding applications like presses and die casting.

Full Description

Parker’s Automation Controller PAC120 was developed for the automation of fast and precise hydraulic processes. Together with the control module PACHC, the compact PLC with integrated, programmable software and EtherCAT master function enables the position and force/pressure control of up to 40 hydraulic axes. In combination with the PACIO modules it can take over complete control.

Due to its extremely compact dimensions and its modular design, the PAC120 can be used in many different applications. Data exchange with other systems is firstly possible via the on-board Industrial Ethernet and OPC UA interfaces. In addition, further communication links can be realized by use of interface and bus modules. This also facilitates system integration in existing control architectures. With the on-board fieldbus options Profinet Slave, EtherCAT Slave or EtherNet/IP Adapter, the PAC120 can communicate with the machine or cell control. External EtherCAT slaves can be connected to the PAC120 by using an PACIO extender module.

Features:

- A single integrated development environment for programming logic, IO, visualization and motion – reduces time for application development

- Optimized for control of presses and die casting machines with two or more control valves

- IEC61131-3 and PLCopen Motion – standardized programming

- Modular system – can be optimally adapted to the respective application with additional modules

- Compact dimensions – requires less mounting space in the cabinet

- Free-of-charge preconfigured software modules – lower programming effort and faster commissioning

- Customized software solutions on request

- Hard- and software from a single source – simplifies purchasing and service

- OPC UA – IoT-ready, prerequisite for networking of machines

- Fieldbus options: Profinet IO/IRT Slave, EtherCAT Slave or EtherNet/IP Adapter

Accessories:

Parker Control Module PACHC

The PACHC ist a control module for high-dynamic and precise control of 1-2 hydraulic axes. It was developed for operation at the Parker Automation Controller PAC120. The device is an EtherCAT slave and is operated at the Parker E-Bus. In conjunction with the bus coupler PACIO-400-00 it can be used in a standard EtherCAT network. The PACHC is connected to local analog sensors like pressure and force sensors and digital position feedback systems for recording actual values. Hydraulic valves are controlled via the analog outputs.

Parker Remote I/O System PACIO

The PACIO System comprises a variety of modules for digital, analog and temperature signals as well as communication interfaces. The modules connect directly to the controller via the built-in EtherCAT bus for local architectures and are extended to remote locations via the extender and bus coupler modules, thus supporting both local and distributed I/O architectures. PACIO communicates natively on the EtherCAT bus, therefore it provides the full functionality and throughput of high-speed EtherCAT to meet the most demanding real-time requirements.

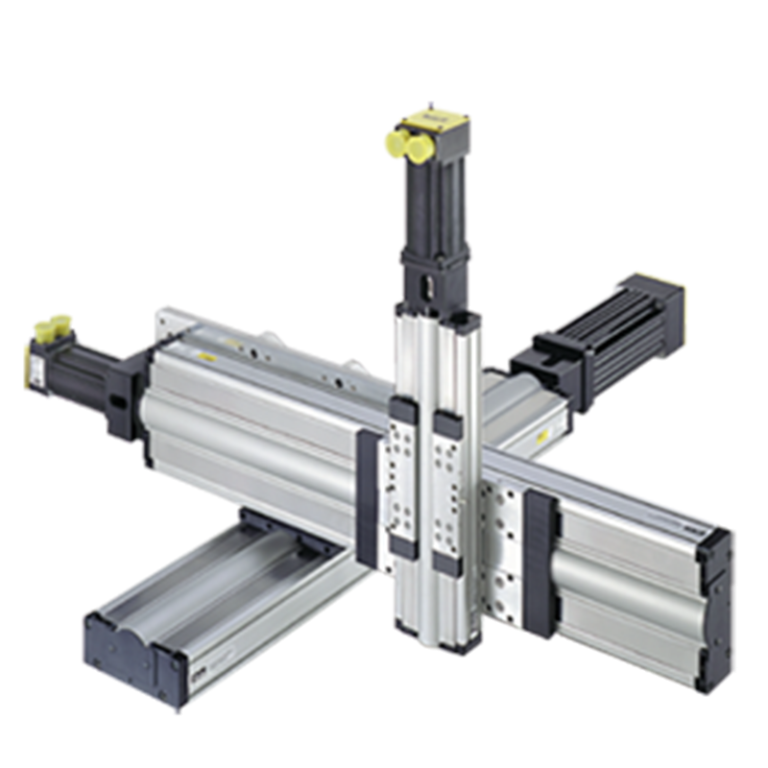

Parker Cylinders and Actuators

Linear Actuators and Cylinders

Parker offers an industry-leading range of linear actuators and cylinders for pneumatic, electric and hydraulic systems. These actuators and cylinders come in a wide range of construction types, ranging from compact light duty aluminum air actuators to motorized electric actuators and heavy duty hydraulic designs.

- Electric Cylinders - ETH series

- Linear Actuators - LCB series, HLE series, HPLA series, HLE series, HLR series

Electromechanical Actuators - ETH Series

ETH Ballscrew Actuators deliver reliable, high-performance operation with advanced electromechanical design features that boost machine productivity. It features 7 oversized ballscrew for smooth, low-friction motion, dual angular contact bearings for balanced thrust, and a clean, extruded aluminum body with integrated sensor grooves. With up to four times higher force capacity and up to ten times longer life from an optimized recirculation system, each unit is designed to improve system efficiency.

Full Description

Parker Series ETH Ballscrew Actuators provide value through proven reliability, efficient performance and the quality that you expect from every Parker Cylinder Division product line. Each Series ETH actuator incorporates design features that are superior in an electromechanical actuator. These benefits include a class 7 ballscrew, multiple stacked angular contact bearings, stainless piston rods, and ISO 15552 pneumatic cylinder mounting construction.

In addition to the class 7 ballscrew and extruded alluminum construction, Series ETH Electromechanical Actuators incorporate a multitude of innovative design features that increase machine productivity through reduced downtime, faster cycle times, and improved system efficiency.

Features

- Class 7 Precision Ballscrew – The oversized ballscrew provides low frictional resistance for smooth motion with lead precision class 7 to ISO standards.

- Stacked Angular Contact Bearings – Series ETH actuators offer (2) angular contact bearings for equal thrust forces in each direction.

- Extruded Cylinder Body – Offers a cleaner, more environmentally friendly design. Sensor groves standard with covers eliminate areas where debris can be trapped on the actuator body.

- Maintenance – Series ETH offers lubrication ports for easy access – lubrication intervals are listed in catalog.

- Use your own motors or complete Parker System including controls.

- Oversized Ball Screws offer 4 times higher force capacity

- Optimized recirculation system offers up 10 times longer life

Manual Stages and Slides

Parker's array of manual positioning stages, tables, and accessories offers a broad range of ball-bearing guided miniature and full-size linear and rotary solutions that accommodate different payload weights and provide varying degrees of smoothness, friction, straightness, and flatness. Accessories such as digital and graduated micrometers and mounting options are available.

Positioning Stages and Tables

Parker's offerings of motorized positioning stages and tables comprise precision rotary tables; cross-roller guided miniature linear positioning stages; dual-square rail-guided linear positioners; high-precision direct-drive rotary stages; and slotless motor-driven, dual-square, rail-guide linear positioners.

Positioning Robots

Parker offers a complete range of precision linear and rotary positioning systems in standard and custom configurations, from miniature stages to precision air bearing platforms. Offering speed, accuracy and repeatability, Parker positioning systems range from pre-engineered linear servo motor tables with “plug and play” modules, to rotary tables designed for motor-driven indexing. The availability of additional Parker products ensures an optimal motion control solution.

Precision Linear Motor Stage – XLM Series

The Parker XLM series is a high-precision linear positioner driven by linear servo motor technology, offering micron-level accuracy in multiple profile widths and customizable encoder options to suit various application needs. Its modular design supports easy multi-axis assembly with integrated cable management, and it offers flexible connectivity with Parker or third-party drives and controls.

Full Description

The Parker XLM series is a precision machined, profiled guide linear positioner which is driven with linear servo motor technology and utilizes selectable levels of linear encoder technology that are configured to match the application need. For machinery or instrument builders who need smooth motion and high precision positioning, the XLM linear positioner provides micron level precision in three different profile widths from 125mm to 200 mm.

One of the main advantages offered by the XLM series is its modular design, allowing multiple axis assemblies to easily be assembled. Whether the application calls for a relatively simple XY configuration or a more complex multi-axis gantry. Integrated cable management helps to provide a clean and easy to install package, saving on the cost of additional components and the time to install them.

Finally, the XLM provides ease of connectivity. Parker’s proven range of servo drives and controls are available for a complete solution from a single, trusted source, but the flexibility of the XLM allows the use of a wide range of drives and controls provided by others.

Features:

- Three form factors: 125mm, 145mm, and 200mm width

- Three ingress protection options

- Six different linear encoder options

- Ironless linear motor technology

- Standard travel options ranging from 40mm to 1500mm stroke

- Efficient cable management system

- Integrated and adjustable limit sensing

- Complete error mapping on each stage – with linear slope correction value provided

- CE and RoHS Compliance

About ONExia, Inc.

ONExia Inc. is a trusted leader in manual process automation, specializing in the design and integration of advanced robotic systems. We are experts in deploying palletizing robots and custom machinery, tailored to meet the unique needs of various industries.

As automation integrators, our goal is to enhance efficiency, accuracy, and productivity through state-of-the-art robotics. We provide end-to-end services, including system development, seamless implementation, and ongoing support, ensuring that our solutions integrate smoothly into your operations.

For more details on our technologies and systems, visit our Collaborative Robotics page.