Integrating automation solutions into your operations can significantly enhance efficiency, reduce costs, and improve production quality. Selecting the right automation integrators is pivotal for the successful implementation of factory automation tools. This guide will walk you through the critical factors to consider when choosing between automation integrators for your manufacturing setup, especially when looking to deploy custom machines and collaborative robots.

Expertise and Experience

The foremost consideration in selecting an automation integrator is their expertise and experience. A company that has a proven track record in successfully executing automation projects, especially in your industry, is invaluable.

ONExia, with its foundation laid in 1984, stands out as an exemplary partner. With out significant amount of experience, particularly with food & beverage and pharmaceutical manufacturers, showcase our ability to handle diverse projects with finesse.

Industry Knowledge

Understanding the unique challenges and needs of your industry is crucial for any automation integrator. This ensures that the solutions provided are not just technically sound but also align with industry-specific requirements, ultimately contributing to the seamless integration and optimal functioning of automation systems.

Technical Capabilities

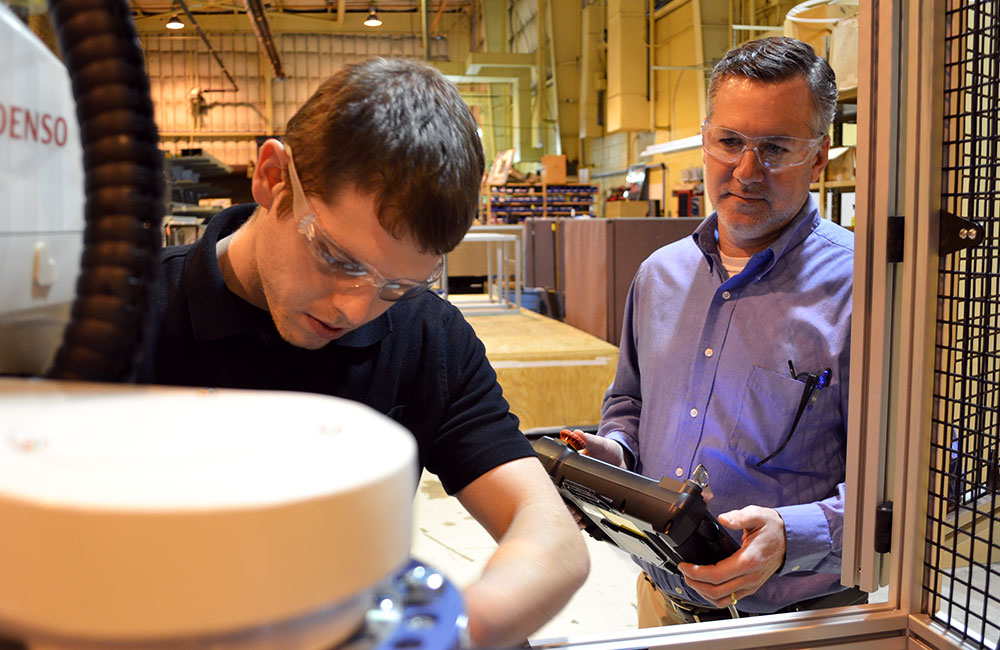

Evaluating the technical prowess of automation integrators is key. This includes their proficiency with the latest automation technologies and systems. Make sure you choose an integrator who can walk you through the three pillars of automation with efficiency and integrity. These stages include:

- Problem Definition: Blearly defining the problem that your automation aims to solve.

- Solution Selection: Choosing the most suitable solution or tool for addressing the identified problem.

- Team Engagement: Involving the relevant team members in the implementation process.

ONExia, through strong partnerships with several leading robotics manufacturers and association with key automation trade associations like A3, remains at the forefront of technological advancements. These relationships enable ONExia to integrate state-of-the-art robotic process automation solutions and offer custom machine builds tailored to client needs.

Customization

The ability to customize solutions is essential. Each manufacturing setup has its own set of requirements, and the capability to tailor solutions accordingly can make a significant difference in the effectiveness of automation integration. Customization ensures that the automation tools not only fit within the physical confines of a manufacturing space but also align with the specific operational workflows, production goals, and regulatory requirements. This level of customization can drastically reduce adaptation time and enhance production efficiency.

A deep understanding of a client’s unique challenges is equally vital. An automation integrator that takes the time to fully comprehend the nuances of a client’s production processes, challenges, and long-term objectives can design solutions that not only address current needs but are scalable for future expansion. This approach ensures that investments made in automation deliver value over time, supporting growth and adapting to evolving market demands and technological advancements.

Reliability

Opting for a partner known for their reliability in delivering projects within the agreed timeline and budget is crucial. This choice minimizes operational disruptions and ensures a smooth transition to automated operations. A reliable partner’s predictability in project execution instills confidence, allowing businesses to plan their production schedules and financial forecasts with greater accuracy. This reliability is a cornerstone of trust, laying the groundwork for a successful long-term relationship between the manufacturer and the team of automation integrators.

Moreover, a partner’s ability to consistently meet deadlines and budgets speaks volumes about their project management skills, technical expertise, and commitment to customer satisfaction. It reduces the risk of cost overruns and project delays that can negatively impact a business’s bottom line and operational efficiency. This consistency is especially important in complex automation projects, where unforeseen challenges must be managed swiftly and effectively to maintain project momentum and achieve the desired outcomes.

Support and Maintenance

Post-installation support and maintenance services are critical for the long-term success of automation projects. A company that offers robust support ensures the sustainability and efficiency of the automation systems installed. Such services include regular maintenance checks, software updates, and immediate troubleshooting assistance, which are essential for minimizing downtime and maintaining optimal performance. This ongoing support safeguards your investment and ensures that the automation system continues to meet production demands efficiently.

Additionally, the company’s commitment to providing comprehensive training sessions as part of its post-installation support is invaluable. This empowers your team with the knowledge and skills required to effectively operate and maintain the new automation equipment. Proper training reduces the reliance on external support for minor issues, promotes a deeper understanding of the system, and enhances the ability to quickly adapt to and resolve operational challenges. This educational approach fosters a culture of self-sufficiency and continuous improvement within your workforce.

References and Reputation

Investigating client references and reviews provides insights into the company’s reputation and the satisfaction level of their previous clients. This can serve as a testament to their capabilities and reliability. Positive feedback from past clients, especially those in similar industries or with similar project requirements, can offer a clear indicator of the integrator’s ability to deliver high-quality, effective solutions. It’s a direct reflection of their proficiency and the positive impact they have had on other businesses.

Additionally, client testimonials can reveal how the company handles change, challenges and maintains relationships post-project completion. Reviews that highlight effective communication, problem-solving, and ongoing support indicate a company committed to its clients’ long-term success. This level of insight is invaluable when seeking a partner that not only has technical skills but also values and prioritizes customer satisfaction and enduring partnerships.

Collaboration and Communication

A robotics integrator that prioritizes collaboration and maintains transparent communication throughout the project duration is crucial for ensuring that the project meets your expectations and requirements. This approach fosters a partnership atmosphere where ideas can be freely exchanged, and feedback is actively sought and addressed. It ensures that any potential issues are identified and resolved early, preventing costly reworks and ensuring that the final product aligns closely with your vision and objectives.

Furthermore, transparent communication establishes a foundation of trust between you and the team of automation integrators. It means being kept in the loop with regular updates, having access to detailed project timelines, and understanding any challenges that arise and the proposed solutions. This level of openness allows for better decision-making on your part and ensures that you remain a key player in the project’s development, ultimately leading to more satisfactory outcomes.

Compliance and Safety

Adherence to industry standards and regulations is non-negotiable. Safety and compliance are paramount in automation projects to protect both your workforce and investment. This commitment minimizes the risk of accidents and ensures that the automation system is both efficient and legally compliant, safeguarding against potential legal issues and fines.

Moreover, compliance with industry standards often signals a level of professionalism and competence, indicating that the integrator is knowledgeable about the best practices and latest safety protocols. This not only enhances the reliability of the automation solution but also boosts the confidence of stakeholders in the safety and efficacy of the project outcomes.

Innovation

Being a factory automation expert requires an automation mindset. A partner that stays abreast of industry trends and demonstrates innovation in their solutions can offer significant competitive advantages.

ONExia’s access to the UR30, a new Universal Robots model with a 30 kg payload, through their relationships with manufacturers, is a testament to their commitment to innovation and providing cutting-edge solutions.

How to Choose an Automation Integrator

Choosing the right team of automation integrators is a strategic decision that can greatly influence the success of your automation initiatives. Factors such as expertise, industry knowledge, technical capabilities, and a commitment to innovation are crucial.

ONExia, with our extensive experience, technical proficiency, and innovative approach, exemplifies the qualities to look for in an automation integrator. Whether it’s the integration of a robotic palletizer, exploring the various types of automation, understanding how heavy 30kg is for your applications, or leveraging the capabilities of the UR30 Universal Robot Arm, ensuring you have the right partner is essential.

Evaluating potential partners on these criteria will help ensure that you select an automation integrator capable of meeting your specific needs and driving your manufacturing operations towards greater efficiency and productivity. For those ready to take their factory automation to the next level, contact us for a free consultation and explore how ONExia can transform your manufacturing processes with customized automation solutions.