UNIVERSAL ROBOTS

The leader in collaborative robots. With over 50,000 cobots deployed globally, Universal Robots are the go-to for manufacturers looking to add flexible automation to their production lines.

Collaborative Robot Integrator

ONExia is an official “Certified Systems Integrator” based in Pennsylvania.

Our dedicated engineering team provides our customers with the systems, service and support needed to implement successful robotic cells into their operations.

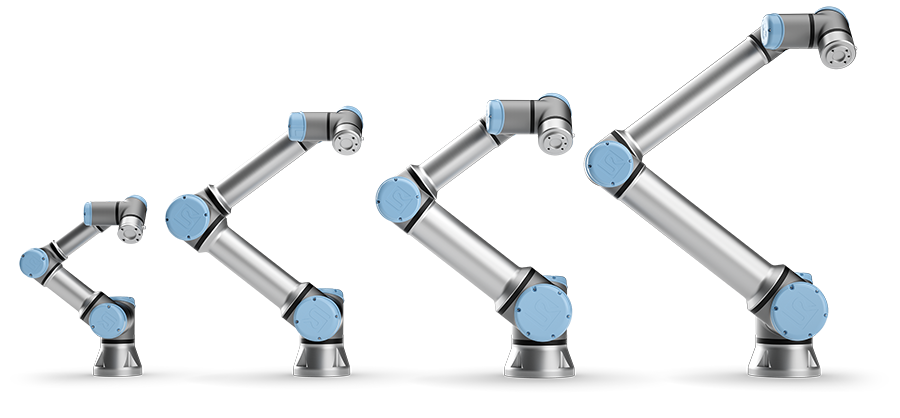

Universal Robots Specifications

The Universal Robots e-Series is the next generation of collaborative robots, designed to optimize throughput using the Polyscope interface.

Each cobot has a different reach and payload, but they share the same precision, accuracy and dependability that make them a valuable addition to any production facility.

UR3 ROBOT ARM

- Reach: 500mm / 19.7 ins

- Payload: 3 kg / 6.6 lbs

- Weight: 11.2 kg / 24.7 lbs

- Footprint: 128 mm / 4.6 ins

- Axis: 6 axis

- IP class: IP54

UR5 ROBOT ARM

- Reach: 850mm / 33.5 ins

- Payload: 5 kg / 11 lbs

- Weight: 20.6 kg / 45.4 lbs

- Footprint: 149 mm / 5.9 ins

- Axis: 6 axis

- IP class: IP54

UR10 ROBOT ARM

- Reach: 1300mm / 51.2 ins

- Payload: 12.5 kg / 27.55 lbs

- Weight: 33.5 kg / 73.9 lbs

- Footprint: 190 mm / 7.5 ins

- Axis: 6 axis

- IP class: IP54

UR16 ROBOT ARM

- Reach: 900mm / 35.4 ins

- Payload: 16 kg / 35.3 lbs

- Weight: 33.1 kg / 73 lbs

- Footprint: 190 mm / 7.5 ins

- Axis: 6 axis

- IP class: IP54

UR20 - 20 kg Payload Cobot

The UR20 is the first of the next-generation high performance cobots from Universal Robots.

The UR20 has been redesigned from the ground up to provide up to 30% more speed and torque, advanced motion control capabilities, and first-class user experience.

- Payload: 20 kg

- Reach: 1750 mm

UR30 – 30 kg Payload Cobot

Increased capacity in a compact design from Universal Robots

The UR30 can lift heavy payloads while maintaining a compact footprint in a collaborative setting. With a 30 kg lifting capacity and a 1300 mm reach this robot can tend larger machines, palletize heavy products, and effectively support high torque screw driving.

- Payload: 30 kg

- Reach: 1300 mm

End-of-Line Packaging Automation

The answer to your labor shortage! ONExia Robotics is a division of our engineering team focused on building turn-key robotic solutions for end-of-line packaging automation.

- Turn-key packaging lines

- Robotic case erectors

- Robotic case packers

- Robotic palletizers

- Vision integration

- Conveyor integration

Collaborative Robot Palletizer

Designed for Universal Robots, the PalletizUR is a turn-key robotic palletizer that is easily added to existing packaging lines where labor is an issue.

- Integrated UR cobot arm

- No teach pendant – drag-and-drop palletizing software

- Turn-key solution – the PalletizUR is not a kit!

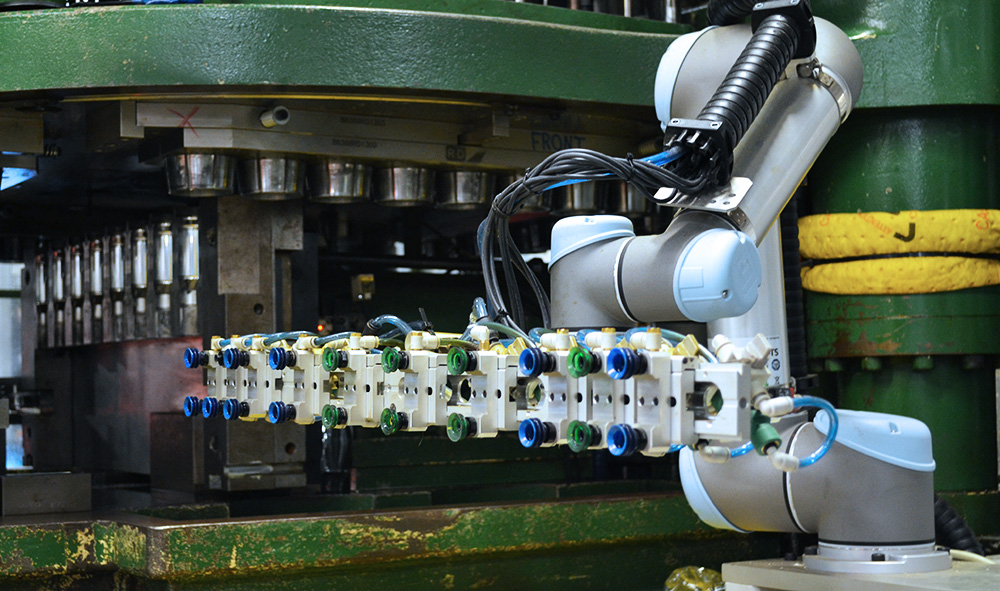

Machine Tending - Takeout Robot

Designed to integrate with blow molding machine, this turn-key system is designed with the flexibility to quickly repurpose as production changes.

SYSTEM FEATURES

- Custom designed end-effector with built in presence sensors

- Mobile with mounts that connect directly to blow mold machines

- Custom software with pre-programmed pick positions

- Fully automated – no human interaction needed!

Material Handling - Case Packer

Built to integrate with an existing manufacturing lines, our robotic case packing cells handle custom shaped plastic parts for final shipment.

SYSTEM FEATURES

- Designed to integrate directly with existing equipment

- Custom end-of-arm tooling to pick multiple parts in one cycle

- Built-in HMI with custom software for simplified usability

- Fully automated – no human interaction needed!