Manufacturers are constantly looking for ways to improve efficiency, reduce errors, and enhance overall productivity. One powerful solution that has emerged in recent years is the use of collaborative robots, or “cobots.” Unlike traditional robots, cobots are designed to work alongside human operators, enhancing the production process while reducing the risk of errors and improving safety by automating repetitive and potentially dangerous tasks. In this article, we will explore how cobots can benefit your general manufacturing operations.

What are Cobots?

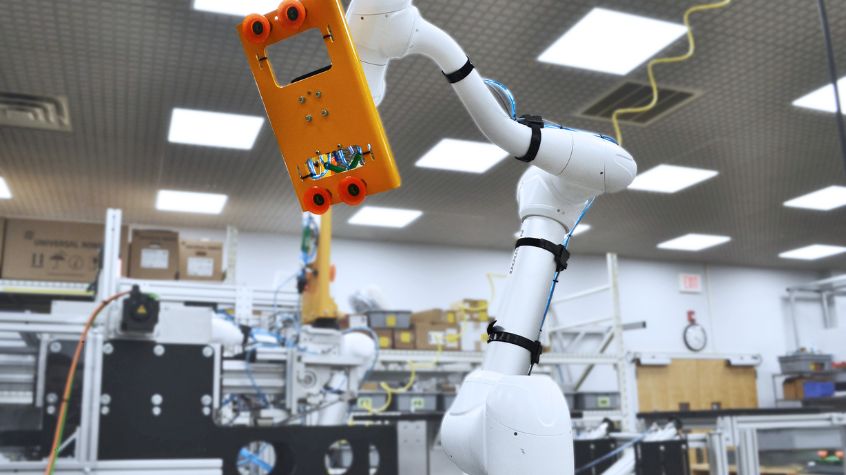

Collaborative robots, or cobots, are advanced machines that can interact directly with human workers to perform tasks such as assembly, packaging, and material handling. Unlike traditional industrial robots that operate in isolation, cobots are designed to be safe, flexible, and easy to integrate into existing workflows. They can be programmed to handle repetitive, time-consuming tasks, allowing human workers to focus on more complex or creative aspects of production.

Why Should You Consider Using Cobots in Manufacturing?

There are several key reasons why incorporating cobots into your manufacturing processes can lead to significant improvements. These include reducing human errors, enhancing productivity, and improving workplace safety.

1. Reducing Errors with Cobots

One of the primary benefits of cobots is their ability to reduce errors in manufacturing. Human workers are prone to fatigue, distractions, and mistakes, especially when performing repetitive tasks over long periods. Cobots, on the other hand, are designed to perform these tasks with high precision and consistency.

For example, cobots can be used to handle quality control checks, ensuring that products meet the required specifications before they leave the production line. They can also be programmed to detect defects, sort items, or assemble products in a specific order, minimizing the chances of human error.

By automating these repetitive and detail-oriented tasks, cobots help reduce the likelihood of mistakes that could lead to product defects, recalls, or delays in production. This results in higher product quality, fewer reworks, and a more efficient workflow.

2. Boosting Productivity with Collaborative Automation

Cobots have the ability to work tirelessly without the need for breaks, which significantly boosts overall productivity. In manufacturing environments where output speed and consistency are critical, cobots can provide a steady, reliable performance.

For instance, cobots can handle tasks such as assembling components like medical devices, packing products, or even managing inventory in real time. This automation allows human workers to focus on more strategic and skilled tasks, ultimately increasing the overall output of the manufacturing process.

In addition to their speed, cobots can also work 24/7 without compromising on quality. This flexibility allows manufacturers to scale production without the need for extensive labor force increases, making it easier to meet customer demands while maintaining a high level of precision.

3. Improving Safety with Cobots in Manufacturing

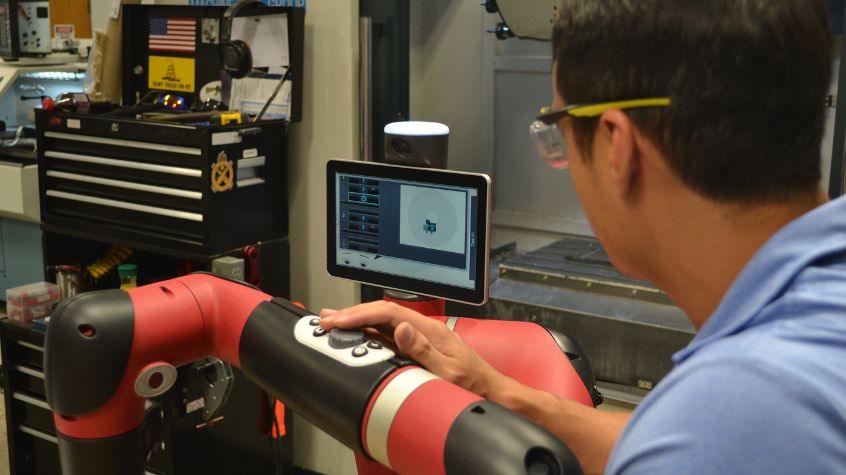

Workplace safety is a significant concern in any manufacturing facility. Cobots are designed with safety features that make them ideal for collaborative environments, where they can work alongside human operators without posing a risk of injury. These safety features include sensors that detect human presence, emergency stop buttons, and force-limiting technology that ensures the robot does not apply excessive force in case of accidental contact.

By taking on tasks that are dangerous or ergonomically challenging for humans, cobots can reduce the likelihood of workplace injuries. For example, cobots can handle heavy lifting, dangerous chemicals, or repetitive motions that could lead to musculoskeletal injuries over time.

In turn, this reduces the risk of costly worker’s compensation claims and increases worker satisfaction by reducing physical strain and repetitive injuries.

How Cobots Integrate into Your Manufacturing Process

Cobots are ideal for small to mid-sized manufacturers thanks to their flexibility, ease of use, and cost efficiency.

- Flexible Integration: Cobots can be added to existing production lines with minimal disruption. They work safely alongside humans on tasks like loading, packaging, and assembly—no major infrastructure changes required.

- Simple Programming and Adaptability: With intuitive programming (even drag-and-drop or manual guidance), cobots are simple to teach and reprogram. This makes them perfect for operations with frequent product changes or small batch runs.

- Cost Efficiency: Cobots are more affordable than traditional robots and take up less space. They reduce labor costs and increase output, which can maximize ROI for manufacturers large and small.

What are the Key Benefits of Cobots in General Manufacturing?

Here’s a summary of the key benefits cobots bring to general manufacturing:

- Reduced Errors: Cobots minimize human error, leading to higher product quality and fewer defects.

- Increased Productivity: Cobots can work continuously, boosting the overall speed and efficiency of your production process.

- Improved Safety: Cobots take over dangerous or repetitive tasks, reducing the risk of workplace injuries and improving employee satisfaction.

- Cost Savings: Cobots can lower labor costs and reduce the need for expensive reconfiguration of production lines.

- Flexibility: Cobots are adaptable to various tasks and can be reprogrammed easily, making them ideal for small to medium-sized manufacturers.

Conclusion: Is Automation Right for Your Manufacturing Facility?

As general manufacturing continues to evolve, the adoption of collaborative robots offers clear advantages in reducing errors, increasing productivity, and improving safety. Whether you are looking to automate specific tasks or integrate a fully collaborative automation system, cobots can provide the flexibility and efficiency your business needs.

To explore how cobots can benefit your facility, learn more about the industries we serve and custom machines.

Contact us to discuss how ONExia can help integrate cobot solutions tailored to your specific needs.