AI-enabled collaborative robots, or AI cobots, are intelligent machines designed to work safely alongside humans. Unlike traditional industrial robots, they use AI to sense their environment, adapt to changing conditions, and optimize production tasks automatically, increasing manufacturing efficiency across diverse industries.

While fully AI-integrated cobots are still in development, manufacturers are already preparing for their arrival. By exploring how these intelligent machines will shape tomorrow’s production environments, companies can position themselves to lead the next wave of industrial automation.

When integrated into future operations, AI-enabled cobots are expected to increase manufacturing efficiency, reduce manual labor, and enhance safety; all without sacrificing productivity. Whether your goal is to streamline assembly, automate inspection, or implement cobot palletizing, AI robotics will reshape what’s possible on the production floor.

What are AI-Enabled Collaborative Robots?

AI-enabled collaborative robots are advanced robotic systems designed to work alongside people in shared workspaces. Unlike traditional industrial robots that follow fixed programs, these next-generation systems will be able to analyze data, learn from experience, and make real-time decisions.

Their core distinction lies in the integration of AI algorithms and sensor data, enabling them to:

- Recognize patterns and adjust to changing environments

- Learn new tasks without manual reprogramming

- Collaborate safely with humans through force sensing and motion control

- Continuously optimize workflows for better efficiency

Today’s cobots already exhibit early forms of this intelligence such as force feedback, vision-guided assembly, and automated palletizing. AI integration will take these capabilities further, allowing cobots to adapt on the fly rather than follow pre-set routines.

How will AI-Enabled Cobots Improve Production Line Efficiency?

AI-enabled cobots will play an important role in improving production line efficiency. These intelligent systems will automate repetitive and time-consuming tasks while adapting to product variations, line changes, and process improvements.

Ways they will improve efficiency include:

- Running continuously without fatigue or slowdown

- Minimizing errors with precision and repeatability

- Handling complex workflows with AI-guided adjustments

- Reducing scrap and improving quality output

- Freeing human workers for high-skill tasks

In short, AI robots enhance both the speed and accuracy of your operations, which is critical to achieving consistent production line efficiency.

What are the Common Applications for AI Robots?

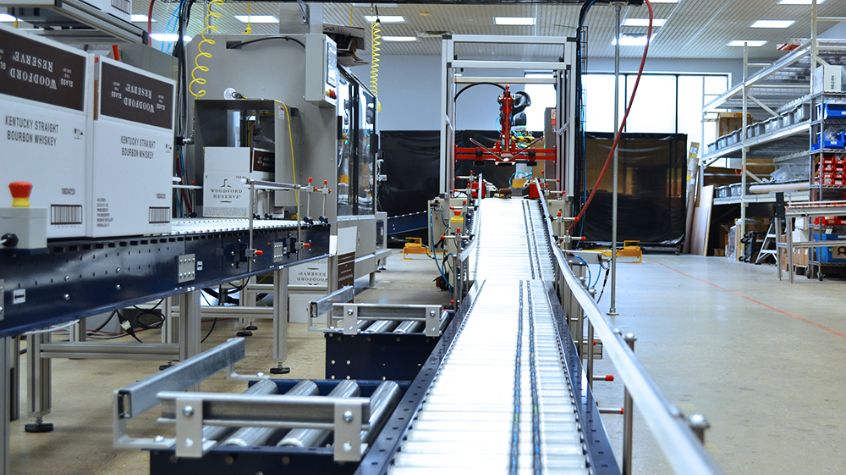

AI robots can be deployed in various stages of the manufacturing process, especially where precision, repetition, and adaptability are required.

Typical applications include:

- Cobot palletizing at the end of the line to automate packaging and stacking

- Machine tending, loading, and unloading materials

- Vision-guided inspection and quality assurance

- Precision assembly, especially in medical device assembly

- Sorting, labeling, or packaging operations

AI-powered cobots are also making significant inroads in regulated sectors like aerospace where accuracy and compliance are essential.

How do Cobots in Manufacturing Work Safely with People?

Cobots in manufacturing are engineered for direct interaction with human workers. They use a combination of force sensors, speed monitoring, and real-time environmental awareness to prevent collisions and respond to unexpected contact.

Unlike traditional robots confined to safety cages, cobots support flexible layouts and hybrid work processes. For example, a cobot can manage the heavy lifting of repetitive tasks while an operator manages decision-making and quality control.

This collaborative model reduces strain injuries, increases throughput, and creates a more ergonomic work environment.

Why Choose a Doosan Cobot?

Doosan cobots are among the most advanced collaborative robots available today. Known for their payload range, precision, and ease of use, they’re built to perform reliably in real production settings.

Doosan cobots provide:

- High payload capacity with smooth motion control

- Long reach and compact design for tight spaces

- User-friendly programming via tablet or direct teaching

- Built-in safety certified to international standards

Doosan’s commitment to innovation continues to be recognized globally. The company was recently honored at the CES Innovation Awards with the 2026 Best of Innovation Award in the AI category and the Honoree Award in the Robotics category. This achievement highlights how AI-enabled cobot technology is moving closer to practical, real-world applications for end users.

As a long-time partner of Doosan Robotics, ONExia integrates these cobots into efficient, production-ready systems and continues to explore how artificial intelligence will elevate performance even further.

What Makes Cobot Palletizing Effective?

One of the most popular and practical applications of collaborative robots is cobot palletizing. It automates the task of stacking boxes, containers, or products onto pallets, a labor-intensive role that’s repetitive and physically demanding.

AI-enabled cobots make palletizing smarter by:

- Detecting different box sizes and weights automatically

- Adjusting patterns for mixed-load configurations

- Operating safely alongside forklift operators and packers

- Reducing bottlenecks at the end of the line

For washdown or corrosive environments, ONExia also offers systems featuring a corrosion resistant stainless steel palletizer base, designed to endure the rigors of food, beverage, and pharmaceutical packaging.

How are AI-Enabled Cobots Transforming the Manufacturing Industry?

As more manufacturers face pressure to do more with fewer resources, AI-enabled cobots offer a flexible and cost-effective automation strategy. They’re helping companies:

- Fill labor shortages without compromising output

- Maintain quality through smart, repeatable tasks

- Reduce floor space requirements with compact automation cells

- Stay agile in the face of changing product demands

Cobots in manufacturing are not just filling gaps, they’re opening up new possibilities. With AI capabilities, they’re evolving from simple task executors to intelligent production partners.

Who Should Consider Deploying AI-Enabled Cobots?

AI-enabled cobots are a smart fit for any manufacturer looking to improve operations without a full-scale automation overhaul. You should consider deployment if:

- Your team is stretched thin or facing labor shortages

- You have repetitive, low-skill tasks slowing production

- Your products change often, requiring flexible automation

- You need to reduce injury risk from lifting or repetitive motion

- Your goal is to increase manufacturing efficiency sustainably

Whether you’re producing high-precision medical components or assembling large aerospace systems, collaborative robots can fit into your process and grow with your operation.

How Do You Get Started With AI-Enabled Cobots?

The best way to begin is by working with a trusted automation partner that understands your production goals. ONExia is a full-service cobot company offering design, integration, and support services for collaborative robots today, while also developing solutions that anticipate the next generation of AI-enabled automation. From custom machines to turnkey palletizing lines, ONExia delivers automation that fits your space, budget, and goals.

Contact ONExia to explore how AI-enabled cobots can increase productivity, reduce labor costs, and future-proof your manufacturing operations.