What Are the Hidden Costs of Not Automating Your Manufacturing Facility?

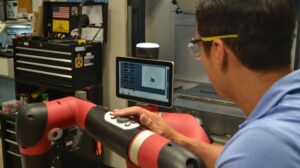

How can you scale production without overextending your team, budget, or facility? For small and mid-size manufacturers, the real risk isn’t just falling behind competitors. It’s the hidden costs of not automating inefficient, manual, or under-automated operations.