For years, food and beverage manufacturers have had to make palletizing equipment work in environments it wasn’t designed for. Walls were built to separate packaging from wash-down areas to prevent corrosion. Machines were rolled out of humid zones. Some plants even resorted to tarping equipment to shield it from water exposure.

We saw the cost of these workarounds and asked a different question: What if a standard palletizer was engineered to fit real conditions instead of forcing plants to adapt?

The answer is here: a first-of-its-kind palletizer base available in corrosion-resistant stainless steel.

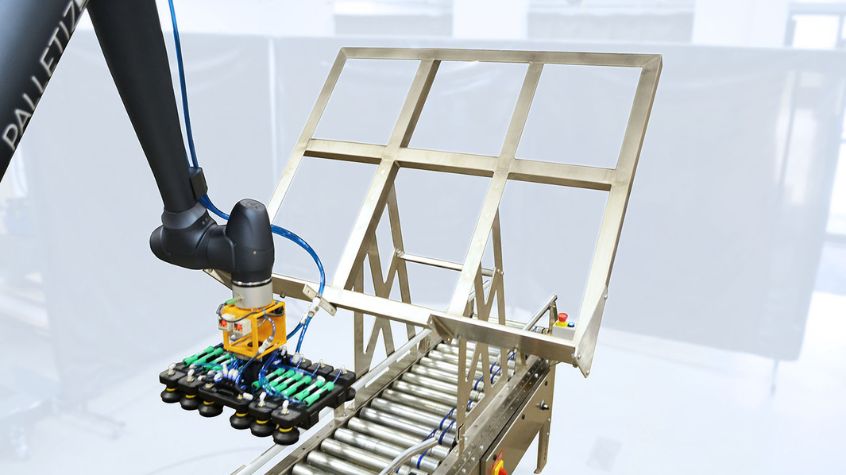

Meet the Gen 2 Stainless Steel Palletizer Base

Our Gen 2 Palletizer is now available with a stainless steel, corrosion-resistant base designed specifically for food and beverage packaging. Built to withstand harsh conditions, this design can be installed near wash-down environments, eliminating costly barriers or relocation workarounds. From pickle packaging plants to coastal facilities, it delivers a long-overdue solution in rust-resistant packaging equipment.

Why We Developed It

Traditional palletizer bases were designed for dry, controlled environments, not the harsh, corrosive food and beverage environments where they’re used. Humidity, cleaning chemicals, and acidic byproducts quickly wear down traditional carbon steel bases, leaving manufacturers stuck spending more on protection and maintenance than on productivity.

That’s why we built a corrosion-resistant alternative to traditional palletizers with carbon steel bases. Widely recognized as the best metal for corrosion-resistant packaging equipment, our stainless steel base resists rust and provides a smooth, non-absorbent surface that’s easier to clean. Using corrosion-resistant materials also extends palletizer life by reducing rust and maintenance requirements.

How Do Our Palletizers Integrate with Other Packaging Equipment?

The Gen 2 Palletizer integrates seamlessly with upstream and downstream conveyors, barcode scanners, and case handling systems through Ethernet and standard I/O. It can also connect with AMRs (autonomous mobile robots) and supports cobot palletizing, making it a versatile solution in today’s connected packaging lines.

Beyond Stainless: More of What’s New in Gen 2

While the customizable corrosion-resistant stainless steel configuration is the big news, our Gen 2 Palletizer Base includes several other upgrades:

- Better accessibility for electrical and control systems, making maintenance faster

- Higher capacity, designed to support the newest, largest robots

- Easier relocation, thanks to a re-engineered design

- Optional stainless compartment for electrical components for customers with especially corrosive environments

How to Choose the Right Palletizer for Your Food Manufacturing Facility

The right palletizer can transform your food and beverage packaging operations. Choosing the best system is about ensuring it fits the specific needs of your facility. Key considerations include:

- Production environment: Is it humid, corrosive, or near a wash-down zone?

- Line integration: Will it connect smoothly with conveyors, scanners, and even AMRs?

- Operational efficiency: Can it reduce manual labor with features like slip sheet placement?

- Scalability: Will it handle today’s throughput while leaving room to grow?

- Flexibility: Can it adapt to different pallet materials, case sizes, weights, or product types?

- Compliance and safety: Does it meet food industry safety requirements and operator safety standards?

What Features Should You Look for in Rust-Resistant Palletizing Machines?

If your facility struggles with corrosion challenges, look for corrosion-resistant palletizer systems that reduce risks of rusting, lower maintenance needs, and extend machine life with features such as:

- Anti-corrosion stainless steel base built for harsh environments

- Stainless steel interior electrical control panel and interior components

- Stainless steel accessories, including conveyors and slip sheet holders

A Corrosion-Resistant Step into the Future of Packaging

The Gen 2 Stainless Steel Palletizer Base is a step forward for standard automation in food and beverage manufacturing. By designing equipment that fits real-life plant environments, we are once again moving the industry ahead in packaging automation.

Ready to see how an anti-corrosion stainless steel palletizer can improve the efficiency and reliability of your facility? Stainless steel bases are available now! Contact us to customize your ideal solution.