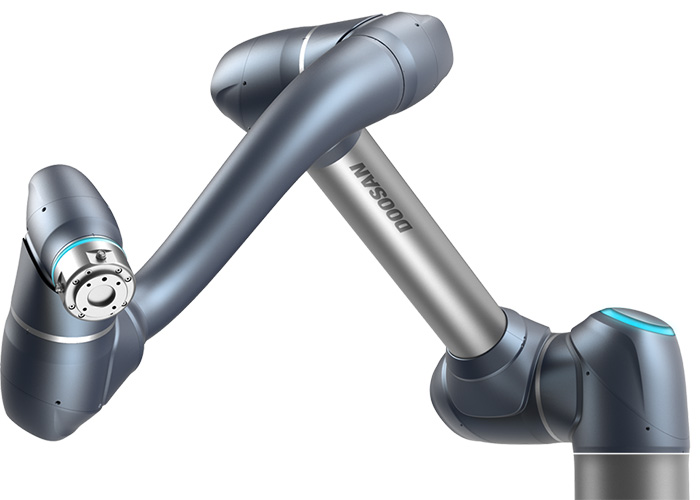

DOOSAN ROBOTICS

Offering a complete line of collaborative robot arms, Doosan Robotics cobots deliver a powerful combination of precision, safety, and flexibility for automating manual processes. Each Doosan cobot is engineered with collaboratively-rated collision detection for smooth performance that upholds the highest safety standards. From light, compact cobots for small-part handling to high-payload cobot arms designed for demanding applications like palletizing and machine tending, the Doosan collaborative robot portfolio offers a solution for nearly any production environment.

Collaborative Robot Integrator

ONExia is a Doosan collaborative robot solutions provider based in Pennsylvania.

As a robotic systems integrator, ONExia designs, builds, and supports complete Doosan based automation cells. ONExia is a flagship provider of Doosan solutions and specializes in the design, integration, and deployment of turn-key Doosan cobot systems. ONExia also offers fully supported access to the complete Doosan Robotics cobot lineup for collaborative robot arms or robotic machines.

Doosan Robots Lineup

Doosan Robotics features five series of collaborative robot arms engineered for a range of payloads, reaches, and capabilities. Doosan cobots provide scalable solutions that automate manual operations such as palletizing, machine tending, assembly, inspection, and material handling.

DOOSAN P-SERIES

P-SERIES is the most heavy-duty Doosan cobot on the market. Designed specifically to optimize palletizing operations, the P-SERIES stacks boxes over 4 feet high without the addition of a lift. With its substantial reach and powerful capacity, the P3020 offers more flexibility than ever before.

- P3020 – 30 kg (66.1 lbs) payload | 2030 mm (79.9 in) reach

Palletizing Solutions

The PalletizHD cobot palletizer is a robust packaging solution using Doosan cobots for superior reliability and payload capacity. This ONExia system is compact, configurable, and completely turn-key.

Doosan cobots are part of ONExia’s wider collaborative robot portfolio. To compare use cases and deployment options, visit our Collaborative Robots overview.

DOOSAN H-SERIES

H-SERIES is the most powerful Doosan cobot on the market. The outstanding 25 kg payload and 6-axis torque sensor are capable of automating the most ergonomically challenging manufacturing tasks.

- H2017 – 20kg payload | 1700 mm reach

- H2515 – 25kg payload | 1500 mm reach

DOOSAN M-SERIES

M-SERIES offers 6 high-tech torque sensors providing the highest dexterity for sophisticated tasks and ensure the upmost safety with the highest collision sensitivity.

- M1509 – 15kg payload | 900 mm reach

- M1013 – 10kg payload | 1300 mm reach

- M0617 – 6kg payload | 1700 mm reach

- M0609 – 6kg payload | 900 mm reach

DOOSAN A-SERIES

A-Series is a cost effective line designed for end-users looking to explore and experiment with collaborative technology within their daily operations.

- A0912 – 9kg payload | 1200 mm reach

- A0912s – 9kg payload | 1200 mm reach

- A0509 – 5kg payload | 900 mm reach

- A0509s – 5kg payload | 900 mm reach

DOOSAN E-SERIES

E-SERIES is the premier cobot in the Food & Beverage industry accredited in hygiene and sanitation. Designed for easy installation in small spaces, it is optimized for food service and preparation.

- E0509 – 5kg payload | 900 mm reach

Sanitation Features

E-SERIES holds NSF Food Zone certification and IP66 rating. The easy to clean, sealed-seam design ensures maximum hygiene and compliance with FDA food safety standards.

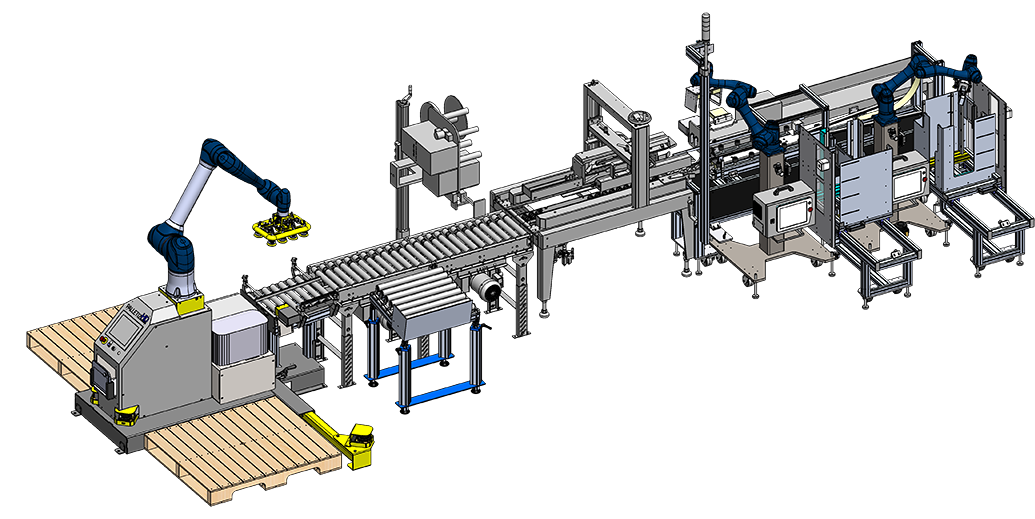

Collaborative Robot Palletizer

The PalletizHD is the most robust robotic palletizer on the market, automating the most challenging line tasks.

- High payload – handle case weights up to 60 lbs, or pick multiple lighter cases at once for increased output

- Vertical reach – stack pallets over 100 inches in height

- Production speed – runs a consistent rate of 7 picks per minute

Robotic Palletizing Systems

Every PalletizHD system is reviewed by ONExia’s team of robotic systems integrators and is delivered as a fully developed, production-ready solution.

- Custom accessories – conveyors, grippers, and slip sheet racks designed specific to every application

- Infeed conveyors – collaborative rated palletizers and integrated safety controls on conveyors

- Slip sheets – added to pallet configurations without human interaction

- Simplified software – drag-and-drop pallet building and conveyor control through the palletizing software

- Support & training – a full team of engineers to assure a successful cobot deployment

End-of-Line Packaging Automation

Using the Doosan line of collaborative robots, ONExia designs and integrates turn-key packaging automation systems.

- Turn-key packaging lines

- Robotic case erectors

- Robotic case packers

- Robotic palletizers

Robotic Case Erector

Automate the task of building and taping boxes with a minimal footprint cobot

ONExia is a trusted robotic case erector supplier, utilizing the Doosan M-Series collaborative robots are easily added to both new and existing lines.

- Fully collaborative design

- Minimal integration to implement

- No programming needed to operate

- Easily adjusted to new box dimensions

Robotic Case Packer

A flexible cobot packing solution for pick and place applications on packaging lines.

ONExia collaborative case packers are a fully customizable, flexible alternative to standard packaging automation.

- Fully collaborative design

- Interchangeable end effectors

- Move between lines based on production demands

- No programming needed to operate

Robotic Machine Tending for Sheet Metal Presses

Custom designed to integrate with an existing sheet metal press, this turn-key system uses 2 Doosan M-Series robots to fully automate a machine tending application.

SYSTEM FEATURES

- Custom carts for handling that mount to the machine frame for moving materials to and from the workcell

- Mechanical positioner for reaching in and out of the sheet metal press

Interchangeable grippers for part changeover - Custom software for controlling the entire workcell through a single HMI

ONExia is more than a Doosan provider. We are a full process automation partner with a long history in motion control, machine vision, and custom machine building. Learn more About ONExia.