Pharmaceutical

Turnkey Robotics for Precision Packaging, Traceability & End-of-Line Automation

We engineer high-precision robotic solutions that seamlessly integrate into pharmaceutical production lines, ensuring repeatable accuracy, optimized throughput, and full traceability. From case erecting and packing to palletizing and specialty secondary packaging, our scalable, turnkey systems eliminate bottlenecks, enhance safety, and adapt to product variations with custom software integration and rapid changeover capabilities.

Enhance Efficiency, Throughput & Consistency

Our robotic automation solutions eliminate bottlenecks, increase packaging speed, and ensure repeatable accuracy, seamlessly integrating into production lines.

- Automate secondary packaging and end-of-line operations with case erecting, packing, and high-speed palletizing for safe, stable loads.

- Keep production moving with automated rejection systems that remove non-compliant products without slowing the line.

- Boost packaging precision and speed with the Tumble Pack Machine.

- Reduce downtime with a smooth transition from Factory Acceptance Testing (FAT) to full-scale production for faster deployment and optimization.

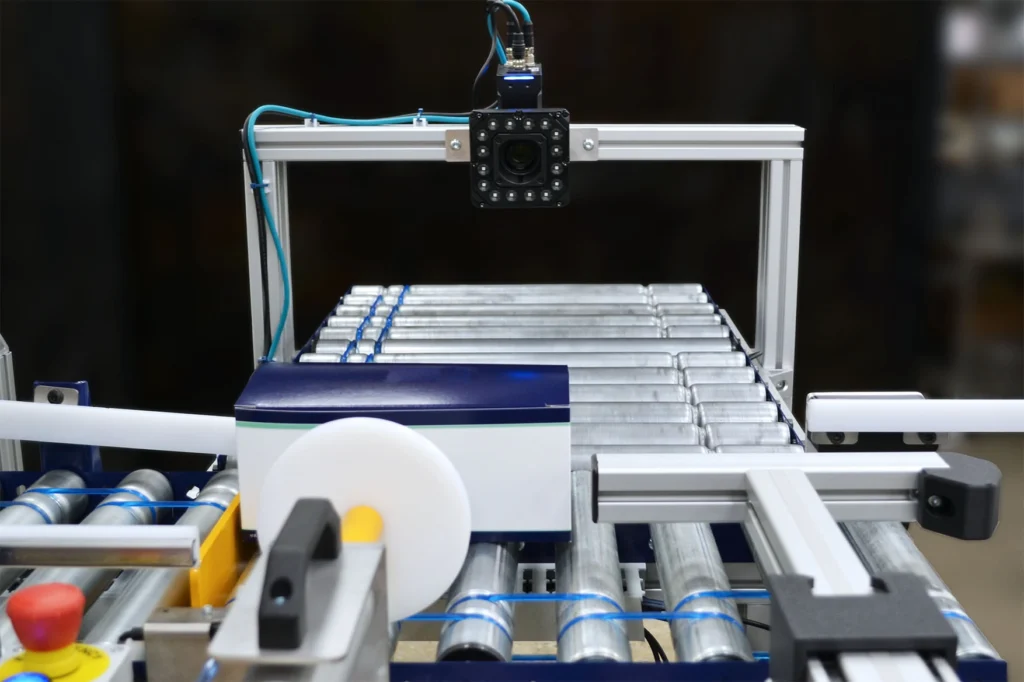

Ensure Traceability & Data Capture

Our automation solutions provide precise product tracking, barcode verification, and seamless data integration, ensuring full compliance with pharmaceutical traceability standards.

- Verify barcode accuracy instantly with integrated vision systems that scan every product and ensure legibility.

- Prevent errors and recalls with automated rejection systems that remove defective or mislabeled products.

- Achieve end-to-end traceability with custom software integration that connects seamlessly with existing tracking systems such as ERG.

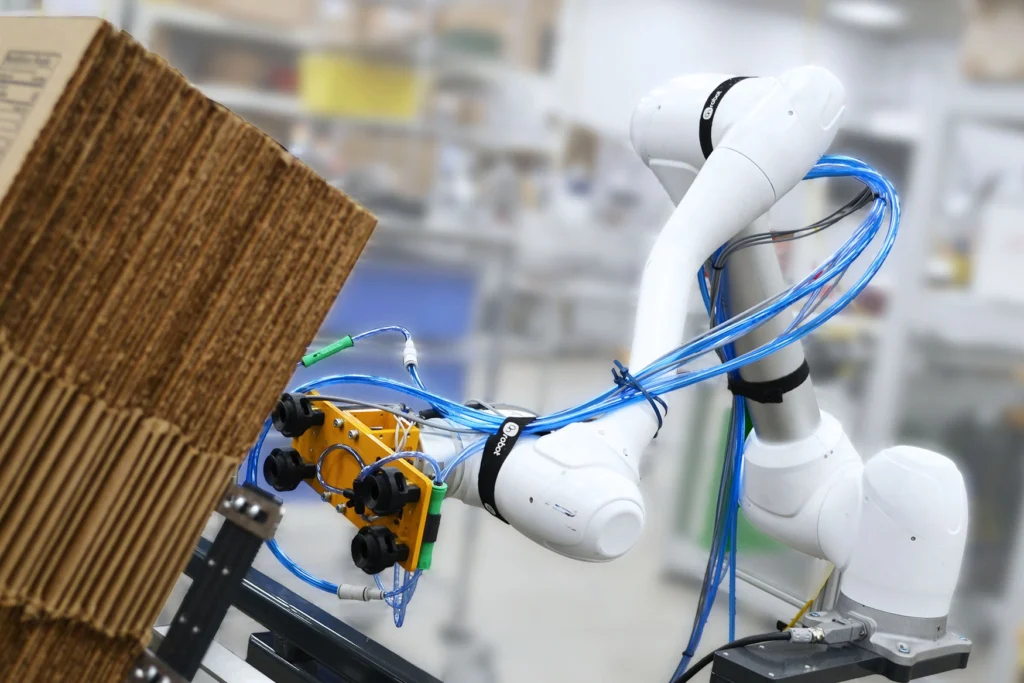

Improve Workplace Safety & Compliance

Our automation solutions reduce workplace risks while ensuring compliance with industry safety standards.

- Eliminate repetitive strain injuries by automating case erecting, packing, and palletizing.

- Enhance ergonomics by reducing manual lifting, pushing, and repetitive handling of pharmaceutical packaging.

- Minimize material handling risks with AGVs and AMRs that automate transport and reduce reliance on forklifts.

- Deploy collaborative robots (cobots) to safely assist workers in packaging operations without caging or guarding.

Adapt Quickly with Rapid Changeover & Flexible Automation

Our automation solutions are designed for quick reconfiguration and seamless transitions between packaging types.

- Adjust on-demand for different SKU sizes, case sizes, and specialty display cases.

- Accelerate changeovers with rapid configuration.

- Easily navigate and control automation with intuitive user interfaces designed for simple operation and minimal training.

Featured Products

See our end-of-line solutions tailored to the pharmaceutical industry:

Future-Proof Your Pharma Packaging Line

With 40 years of expertise, we deliver turnkey automation solutions that help pharmaceutical manufacturers increase efficiency, ensure compliance, and adapt to evolving industry demands. Our systems are designed for seamless integration, precision, and long-term reliability, eliminating bottlenecks and enhancing production consistency.

As your automation partner, we provide customized, scalable solutions and dedicated support to help you optimize performance, reduce labor dependency, and maintain high-quality standards. Whether expanding capacity or improving traceability, our expertise ensures your operations run smoothly, efficiently, and compliantly—now and in the future.

Contact us to start optimizing your pharmaceutical packaging today.